What is Packhelp’s DTP service?

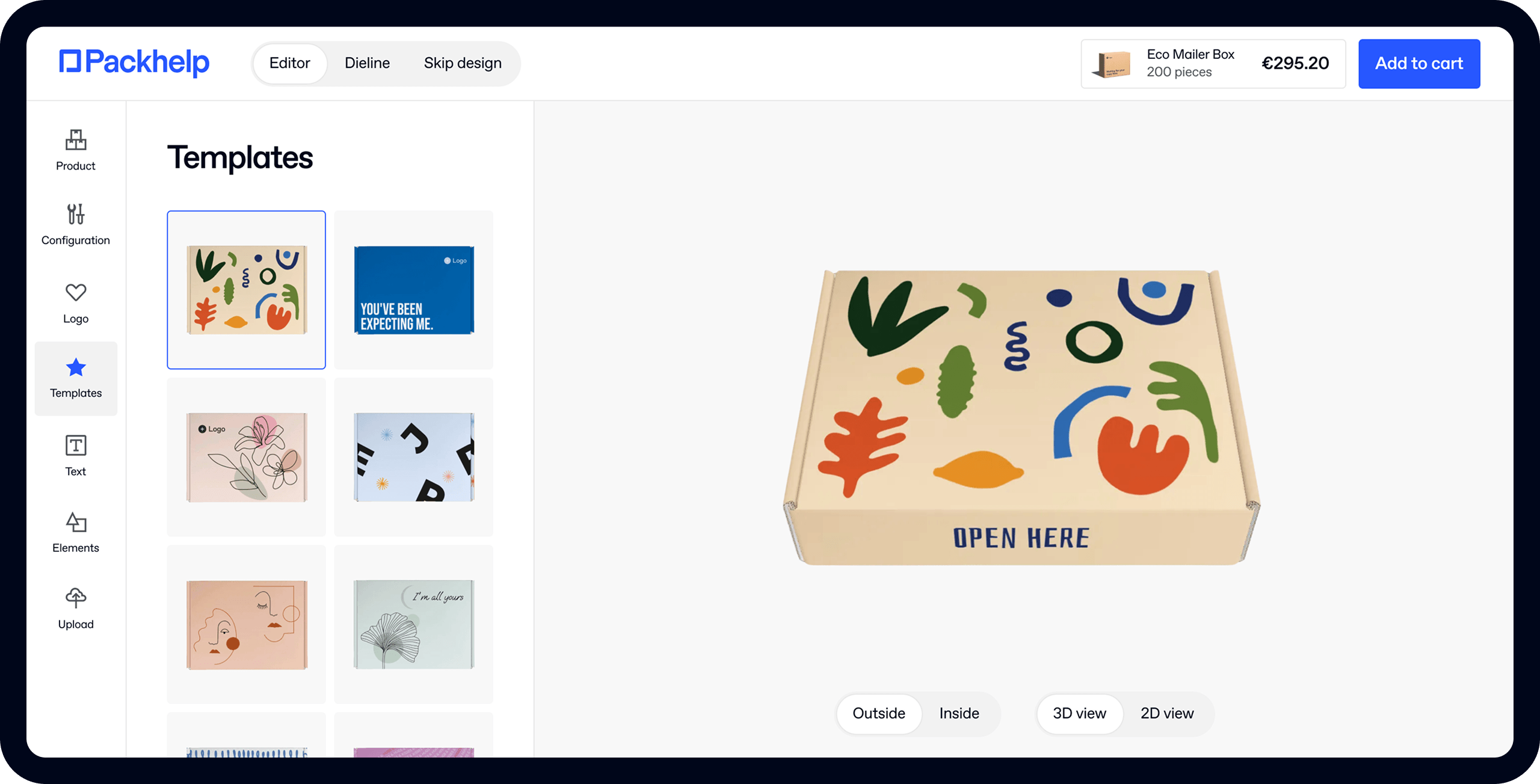

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

Packhelp’s DTP (Desktop Publishing) service is a field of graphic design that specialises in preparing digital designs to be printed onto a physical medium.

Every order made with Packhelp, whether submitted on a dieline or created in our editor, goes through the hands of our DTP team to ensure that your design is optimised and will transfer onto your packaging as best as possible.

In other words, it’s quality control.

This article will give you an idea of precisely what the DTP team will do to your design and how it can impact the overall outcome of your packaging order.

You’ll also see how our ‘Print Expert Check’ service can solve any possible problem in your design.

One thing to remember is that any changes the DTP team make to your design must be approved by you before it goes to print.

DTP elements

There are 4 basic elements that the DTP team checks.

- Colours

- Formats

- Printing shifts

- Missing elements

Let’s take a closer look at each.

Colours

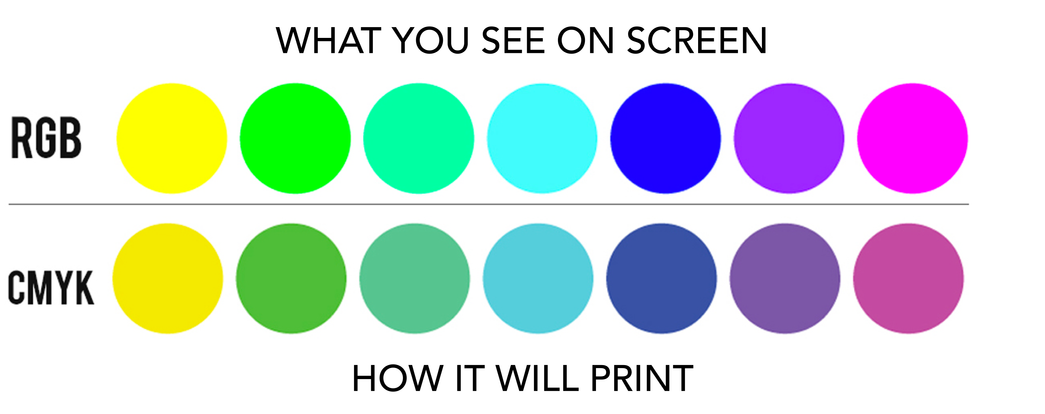

Printing a design that you made on a screen onto a physical medium requires the colour profile to be converted from RGB (the colour profile of modern screens) to CMYK or Pantone (depending on the printing technique).

This change happens automatically, but from time to time, there are noticeable differences in the shades of some colours.

There are several things to keep in mind here:

- The colour difference cannot be avoided with some more saturated shades

- Colour converting websites and tools do not always show the colour difference

- The same colour shades look differently on different materials (eg. kraft material absorbs the ink making pastel shades much duller)

Here you can see the difference between the same design being printed on a white laminate and on kraft paper:

The Print Expert Check will:

If you pick our Print Expert Check at the checkout, our DTP team will:

- Correct the colour palette on each item to make it look as accurate as possible and consistent over all surfaces.

Formats

There are two file types used in printing your design onto a physical medium. Vector or raster (sometimes called Bitmap) are used interchangeably but also depending on the printing process.

Vector images are images made up of lines and points. They can be made as large or small as needed without quality loss.

Raster images are created with a grid of tiny pixels, allowing more detail, but can’t be scaled up without pixelation.

Vector images are commonly saved as .svg, .eps, .ai or .pdf. They’re best for logos, text, QR codes and barcodes.

Raster images are usually .jpg, .png or .pdf and are best for photos and graphics.

What will the DTP team do?

If you submit a design using a logo that, for example, is a raster .jpg file and not a vector .svg file, our DTP team will check that the logo (or other elements) can be printed at the required quality.

If it can’t, they will ask you to deliver the logo in the correct file format, accept the pixelated design or change the design.

Some printing techniques also require only vector file formats. The DTP team can switch formats both ways, but it’s not always possible without severely sacrificing the quality of an image.

That’s why using high-resolution images is essential - it means that your logo can be made smaller without losing definition. Aim for a resolution of 300dpi or higher.

It’s also important to mention a common problem with line thicknesses and fonts. A digital computer screen is great at recreating thin lines and small fonts, but that can’t always be physically printed.

The Print ExpertCheck will:

If you pick our Print Expert Check at the checkout, our DTP team will:

- Convert low-quality images into a lossless format

- Redraw or adjust small elements to preserve their details in the print

- Check font styles and sizes for possible print issues

Printing Shifts

Our printing machines run at a very high RPM with lots of moving parts and a lot of vibrations.

While these incredibly complex machines are designed to minimise those vibrations and ensure quality, sometimes things move during the printing process.

That’s why we encourage you to not put vital elements like logos and text too close to a fold or an edge.

Margins, bleed lines and cut lines ensure that every element of your design stays where it should be, even if the final design is out by (what is never more than) 3mm.

What will the DTP team do?

Our DTP team looks over your design and ensures that elements like logos and text are far enough away from edges and fold lines. The team also extends elements of your design, like patterns, over the bleed line to ensure that the final print is coherent and consistent.

The Print Expert Check will:

If you pick our Print Expert Check at the checkout, our DTP team will:

- Adjust and extend element

- s over bleed lines to ensure they’re printed

- Fix misaligned elements that go beyond edges or spam multiple sides

Missing elements

If you design your packaging on a dieline and submit it to us, you must ensure that all the elements of your design (logo, text etc) are embedded in the design.

If not, your design will be printed without those elements.

What will the DTP team do?

The DTP team checks your design in Illustrator to ensure that all the corresponding files are attached. If they’re not attached, they’ll reach out to you and ask you to send them separately.

Protip: Here’s how to make sure your designs are embedded in the file:

In Illustrator, select your image in the Links Palette, click on the arrow in the top right corner of the palette and select “Embed” from the drop-down menu. You will now see a box next to your image in the Links Palette. - This means that the image is embedded within your document.

Summing up:

Packhelp’s DTP team are expert graphic designers and they’re miracle workers when it comes to the world of printing.

They’ll inspect your order no matter what, but if you add the Print Expert Check, their expertise will help make the little things in your design really stand out and look as good as possible.