Q2/22 – It’s all about the data.

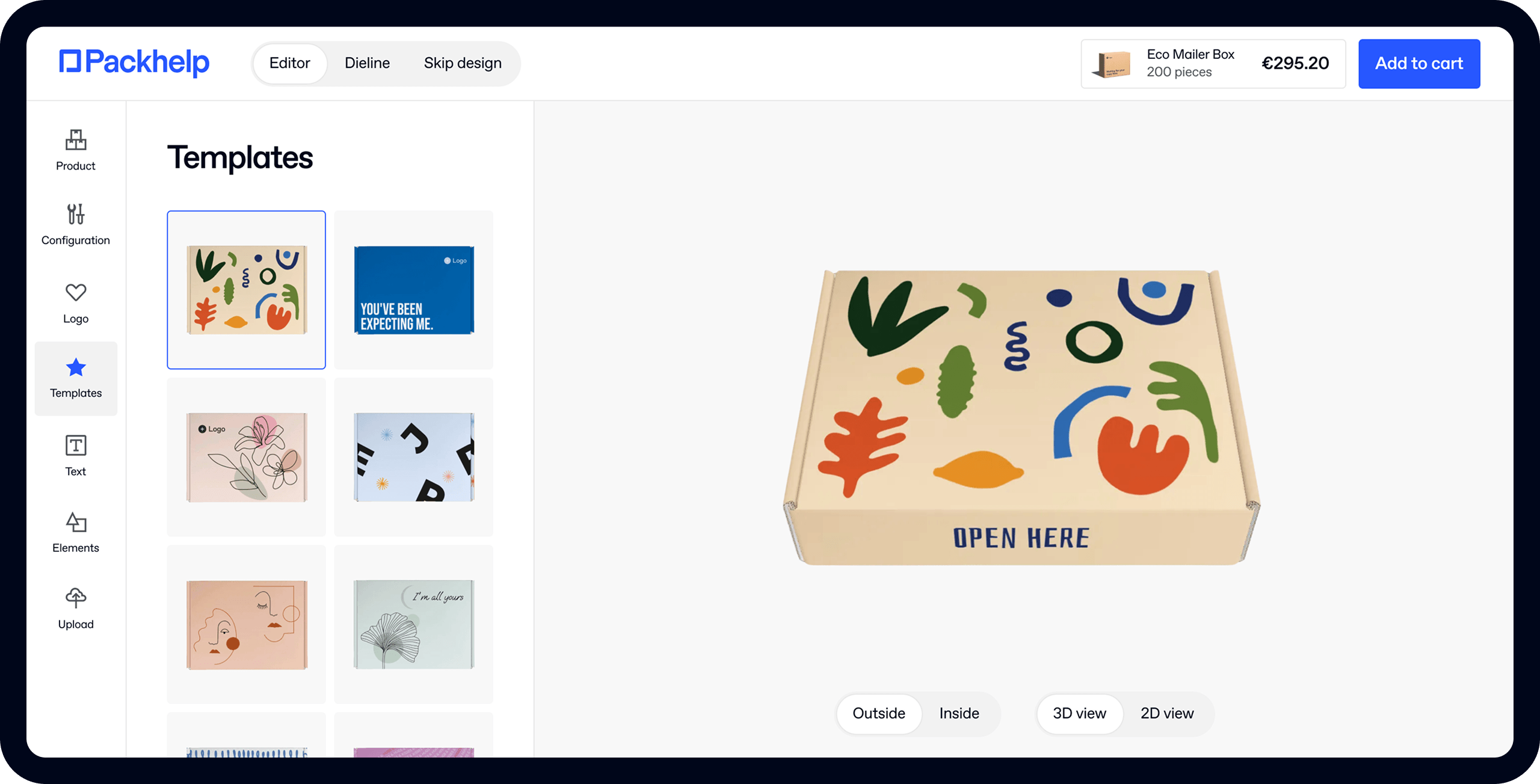

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

Q2 Sustainability Summary

It's all about the data.

Running a business that connects suppliers and customers creates a fantastic opportunity for introducing systemic changes. We realised that the potential of Packhelp's sustainability efforts lies in stimulating change among both ideas of our business. However, before executing a meticulous plan, we checked this assumption by taking a closer look at the data, associations gathering the packaging world, our stakeholders, and our procedures. Here's the overview of all the initiatives that we ran in Q2.

Table of contents

- Data collection

- Carbon Calculations

- Interseroh

- Democratising FSC-C151608 Certification

- Connecting with like-minded people

- Natureef

- Listening to the industry

- A meeting with stakeholders

Data Collection

In the last quarter, we updated our catalogue of eco properties to make it easier for our customers to learn more specifics about their packaging products. It seemed like a tried and tested solution at first. To be 100% transparent, we included each packaging material's advantages and disadvantages. However, we had a gut feeling that we could do more. In Q1, we built a qualitative assessment of our eco properties; now, it's time to compliment them with quantitative data and back it up with international certificates.

Measuring our carbon footprint

Working in the packaging industry, we are privy to industry-specific knowledge. Simply put, it's easier for us to decipher and compare specific definitions because we know the complexities and technicalities of what's being said. But this is not the presumption that we want to make when it comes to our customers. Businesses tend to shift responsibility to the consumers, so we decided to go the other way. Despite a comprehensive description of a material's eco properties, comparing their environmental impact without specific knowledge was still hard. That's how we arrived at the idea of measuring the carbon footprint of each of our products. This move means we can present the data numerically that would be understandable to everyone, regardless of their knowledge of the packaging industry or other technical specifics.

Building cross-industry carbon awareness

We decided to calculate the carbon and water footprint of the life cycle of 13 best-selling packaging solutions from our curated portfolio. They make up 40% of all orders. Why only 13, you may ask? We prefer to take several small steps with a real impact than one big one that won't change a thing besides leading us towards complacency. After calculating the environmental effects of these 13 products, we'll do the same with every product in our product range.

The starting point of the calculation for this particular research was the carbon emission of a ton of cardboard. This means that each product variant had to be weighed before it was possible to tally up its impact. The weight of a package depends on its size, raw material used in production, and thickness. Each packaging product that qualified for research has different sizes and logistic variants. All in all, we checked many different variants and suppliers, which led to over 300 combinations in total.

The biggest challenge in measuring the carbon footprint for Packhelp's products was getting the data. We had to delve deep into the specifics of each supplier's processes like the location of the sourcing plant, energy consumption to produce Packhelp's orders and route of transportation of each product to our warehouses.

“We believe that by being transparent about this data, we will impact the future purchasing decisions of new and existing customers. Having a choice between a manufacturer who is not environmentally responsible and one that cares and shows results is a fair tradeoff”, comments Artur Stańczuk, the company's Chief of Strategy.

The findings for the first products that underwent the research are already on our website! Look for mailer boxes, mailer bags, ecommerce delivery boxes, product boxes, wine boxes, two-piece product box & shipping boxes.

Interseroh

Another thing that we checked is the recyclability of our products. To comply with the increasingly stringent recycling targets required by law (e.g. German VerpackG) and to ensure that waste is processed into high-quality recyclates, materials must be designed for recycling. That means that they have to be suitable for proper collection and reliable sorting, as well as being recycled into a recyclate.

We partnered with an international research agency, Interseroh, who conducted laboratory tests on our packaging to check whether our packaging passes smoothly through after-life processes and is therefore truly 'made for recycling'. We obtained an internationally confirmed certificate stating that 99% of the packaging from Packhelp's curated* range (everything available in our online store) complies with EU and UK recyclability standards.

Interseroh has been delivering tailor-made, integrated environmental services for customers in every industry since 1991. They are specialists in closing loops, preventing waste, and conserving resources. They have already served over 20,000 customers and operate in 32 sites in 7 countries.

Here's a list of products that received Made for Recycling certificate:

- Mailer box (all variants, including full-colour mailer box)

- Product box, wine box, two-piece product box

- Packaging tape

- Kraft tape

- Paper bubble wrap

- Paper bag

- Paper mailer

- Self-adhesive pockets

- Poly mailer

- Packaging paper

- Tissue Paper

- Cardboard envelope

FSC Certification

We are proud to share that we have introduced a revolutionary feature in our Online Creator. From the end of June, everyone can add the FSC® certificate directly to a packaging design, straight from our website.

"What's so revolutionary about this project?"

Before this feature, each design project with an FSC®-C151608 certificate had to be sent to Bureau Veritas, a certification body approved by the FSC®, who manually approved each and every use of the logo. It was time-consuming, burdensome, and, above all, expensive.

To make it possible, we adjusted our technology to match FSC® Standards so that we could automate the process. Our online tool ensures that the certificate is positioned in the right place, prevents other graphic elements from overriding the approved design of the certificate, and only costs 20EUR. To double-check the compliance with the FSC®, we trained our employees (cheers to the DTP team) to be able to approve the designs and created an entirely new internal approval process. The whole project gained the final approval from the official FSC® certification body.

"To sell FSC®-certified personalised products at Packhelp, we had to ensure that all participants in the supply chain were also FSC®-certified: from the paper mill, the packaging manufacturer, to the printing house, and finally to Packhelp. This is just one more example of how we are committed to providing sustainable packaging for every business", comments Zuza Mazurek, Head of Sustainability at Packhelp.

For now, this feature is available for eco mailer boxes, eco white mailer boxes and ecommerce delivery boxes, which make over 30% of all orders from our online store. But of course, our supply chain team is working on expanding the process for other products from our portfolio.

Listening to the industry

To build our long-term sustainability strategy, we engaged in a dialogue with our external stakeholders: customers, suppliers, partners, and investors. The whole process aims at understanding our impact in the ESG areas and is supposed to give us food for thought and insights on our way forward.

So far, we have held two meetings, one in Polish and the second in English. Both of them were conducted by an external moderator. Our representatives took part as observers and listened closely to the expectations and opinions. The process was performed according to 3 standards: AA1000APS (Principles Standard), AA1000SES (Stakeholder Engagement Standard), and AA1000AS (Assurance Standard). The results of the stakeholder engagement will be part of the long-term strategy for ESG at Packhelp.

We believe that it's crucial to source knowledge from diversified sources. That's why we also joined NATUREEF. It is an association that brings together companies from the packaging, chemical, and food production sectors that implement the latest technologies, research and development projects and care for the natural environment. Natureef strives to be a platform for information exchange to usher in a change in the packaging industry. The team has extensive experience in intelligent and active packaging, industry 4.0, and circular economy, so it seemed a perfect fit for us.

Conclusion

In Q2, we focused on expanding our numerical knowledge by conducting recyclability and carbon footprint analyses by listening to our stakeholders and joining Natureef. We hope that this approach will bring the results in a long-term perspective. Last but not least, a huge thanks to all the certification bodies, research agencies, organisations and Packhelpers who made it all possible! You prove that sustainability is truly a joint effort.