What Are Packaging Procurement Lead Times? How Important Are They?

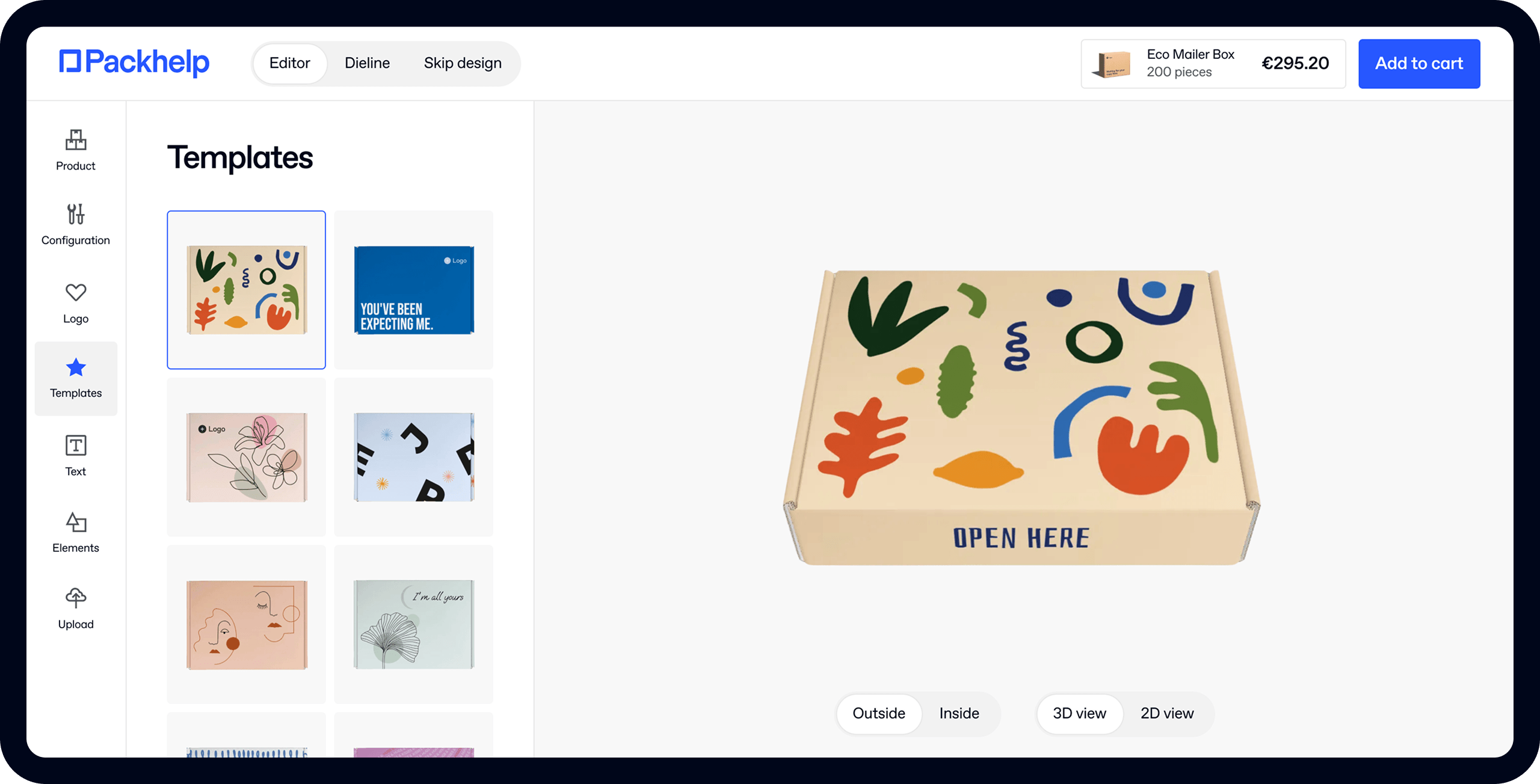

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

- What is lead time?

- What is the lead time meaning in procurement?

- What is lead time in purchasing?

- What’s the difference between lead time and…

- Lead times in the packaging industry

- Why lead time is important in procurement

- Factors that influence lead time

- How to lower and optimise lead time in procurement

- Conclusion

Your business relies on other businesses to help you get the job done.

So you need to know how quickly those businesses can get you their product.

Every order for materials that come into your possession has a lead time. Knowing this lead time and working with it, is key to making your supply chain operate smoothly and efficiently.

Packaging is part of your supply chain that needs some attention in order to operate smoothly

In this article, you’ll see:

- What is the lead time meaning in procurement?

- Cycle time vs lead time and others - what’s the difference?

- Lead times in the packaging industry.

So let’s jump straight in.

What is lead time?

Lead time is the amount of time between starting and finishing a process.

Lead time is important to companies who are either buying or selling in the procurement, project management, supply chain and manufacturing industries.

An accurate definition of lead time varies from industry to industry, but one thing remains constant - low and reliable lead times are great for all parties.

What is the lead time meaning in procurement?

Lead time meaning in procurement is measured from the first effort to acquire a good or service right to the point of its arrival or completion.

Awareness of this time is integral to smooth and efficient business operations.

Knowing the lead time for all products and elements of your operations is a great way to ensure efficiency and healthy cash flow.

This means your business can operate smoother and easily navigate any problems caused by external factors when they do arise.

It’s important to note that procurement lead time includes the time taken to identify the need and find a solution to the product - not just the time taken from ordering to receiving.

Let’s use custom packaging as an example.

When ordering custom packaging for the first time, your procurement lead-time begins when you first start searching for a custom packaging supplier and finishes when your order arrives.

What is lead time in purchasing?

Lead time in purchasing is the time taken from ordering a product to receiving it.

If you plan to order a product regularly, the purchasing lead time will have more of an impact on your operations.

That is to say, procurement lead time is often a one-off expense. You only need to find a way to solve a problem and source a product that does so once.

Again with custom packaging, your purchasing lead-time begins when you place the second order of your previous packaging design and finishes when your order arrives.

So what’s the difference between procurement lead time and purchasing lead time?

You’ll notice in the picture above that there are few other terms.

Here’s what they mean:

What’s the difference between lead time and…

Production lead time:

Production lead time is the time taken to get a job done and deliver the output. It begins when your vendor starts to manufacture, source or fulfil your order and ends when it is ready for delivery.

Turnaround time:

Turnaround time is the same as production lead time but ends when you take delivery of the order.

Lead time vs cycle time:

Cycle time is the time that elapses between your business placing one order for a product and another order for the same product.

Process lead time:

Process lead time is the time it takes for you to make a purchased item available on your shelves.

This is measured from the moment you take delivery and includes inspection, quarantine and internal distribution times.

Lead times in the packaging industry

At Packhelp, we work with procurement specialists and supply chain managers on the daily.

Thousands of brands rely on us to get them their packaging when they need it, so we know a thing or two about packaging procurement.

Want to see how custom packaging can help your brand? Click here to get a quote

Here’s what the average procurement lead time of a custom packaging order looks like:

Why lead time is important in procurement

Knowledge of your own, as well as your vendor’s lead time, means that your business operates efficiently.

If you’re a procurement manager yourself, accurate knowledge of your vendor’s purchasing lead times means that you accurately calculate the best time to place another order.

And as we all know, having too much or not enough stock is a major problem.

On the other side of the coin, knowing your own production lead time means you can give your customer a more accurate picture of when they’ll receive their purchased product.

This, in turn, gives them a better buying experience.

Below you can see an example of telling a customer when their order will arrive:

Here’s why lead time is so important in procurement and purchasing:

Supplier lead time

The lead time of your suppliers tells you how long you’ll be waiting for a product.

When you know this time, you’re able to plan accordingly, order ahead of time, and plan your own manufacturing and fulfilment process appropriately.

Knowledge of your vendor’s purchasing lead time helps you figure out which ones present the best value for money.

Your own lead time

When you know your own company's lead time, you can work toward a lean and more efficient supply chain. This will, in turn, lower your operation costs, and free up cashflow.

A lean and efficient supply chain also means you provide a better service to your customer.

84% of consumers say they wouldn’t return to a brand after one poor delivery purchase, and long delivery times can even prevent purchase in the first place.

Knowing how long it takes for you to send an order once it’s received means you can eliminate your customer’s fears and give them a better buying experience.

This is just one of the many reasons why it’s important that a supply chain manager or procurement manager has a good idea of as many lead times as possible.

The more information you have, the more informed the decisions that you can make.

In summary, accuracy in procurement and supply chain management helps processes align and work smoothly.

Factors that influence lead time

There are a staggering amount of variables that affect both your lead time and the lead time of your suppliers.

Problems can, and often do create a ripple effect elsewhere in your supply chain.

Being aware of where problems can come from helps you solve them quickly and get back to business.

Staffing

People are what make your business function. However staff can get sick or injured, and their replacements may need to learn how to replace them.

This takes time and in many cases, impacts the lead time of a product.

Vendors and suppliers

It’s been said that a poor supplier will cause more problems than poor materials. Your organization needs a supplier who can not just meet your expectations the first time, but with each and every order that you place.

A quality relationship with suppliers that know the product inside out is crucial to making sure that your supply chain runs smoothly. It’s important to stress the value of a quality relationship with your suppliers.

It’s important that you only stay loyal to a supplier for the right reasons and the lowest price isn’t the only reason to consider.

Geographic location

Your location plays a significant role in how quickly you get your products. Unsurprisingly, the location of your suppliers is just as important.

If either party is located away from major delivery hubs, sending and receiving materials is only going to take more time.

A good supply chain manager considers the location of local logistical hubs to operate in a smooth and timely manner.

See how Packhelp's range of custom packaging supplies can help keep your packaging costs down

Business days

Cultural holidays are often overlooked in daily supply-chain operations.

A global economy means that more business happens from all corners of the world, but it’s often done without the consideration of local holidays and other cultural events.

July 4 is a national holiday in the USA, but it’s just any other day in most other countries.

Supply chain managers should be aware of the local holidays of their suppliers, as an extra day added to an order’s lead time can have huge ripple effects elsewhere in your supply chain.

Customs and quarantines

If you’re ordering or shipping internationally, your deliveries and purchases may be subject to local customs and quarantine laws.

Also, consider that viral pandemics like the COVID-19 situation and its disastrous effect on supply chains.

This pandemic not only affects people (another lead time factor) but also means fewer deliveries are going to certain parts of the world.

How to lower and optimise lead time in procurement

So now that you know exactly what is lead time in procurement and purchasing, it’s time to take a look at how you can optimise your supply chain in order to keep lead times down.

Buy local

As you read above, geographical constraints are a major factor in lead time.

That’s why working with a supplier that’s geographically close to you can seriously lower your lead times.

If your vendor isn’t physically close to you, make sure that they’re close to a major transport hub so that their products can get to you in the most efficient manner.

Order less, more often

Price breaks are one of many incentives that suppliers use to make you order larger amounts in one purchase.

While this is great for them, the lower per-unit prices often mask other problems for you. Storage constraints and tied-up cash just being a few of them.

Placing a large order with your supplier also means that you’ll have a longer lead time - there’s simply more product to supply you with.

Consider ordering smaller quantities every month or two, rather than larger orders every 6 months.

Sure, you may pay a higher per-unit cost, but that may be overshadowed by other benefits like less inventory to manage, more space on your shelves - and a shorter lead time.

Forecast your sales

Sales forecasts are a godsend for anyone in management, especially supply chain managers and procurement specialists.

That’s because their main purpose is to roughly predict the future.

By using data and previous sales to predict seasonality, you’re able to estimate what you need to meet that demand.

Using sales forecasts and the lead times of your suppliers allows you to put together a rough yet reliable picture of when you’ll need to order certain supplies to keep up with demand.

Spend some time with your sales staff and try to get a rough idea for both short and long terms sales predictions.

Use this information, combined with the lead times of your suppliers, to place orders at the correct times.

Standardize

If the supplies that you require are custom, unique, or made to order, that’s going to create a longer time between ordering and receiving.

Check with your internal managers and discuss whether any products can be standardized - that is to say, modify the job so that one product can be used for multiple purposes.

See how Moonsling uses a standardised packaging and unique packaging design to keep costs down

Another tip to help standardize your products: use a supplier that’s actually a specialist in the application of their products.

A good supplier is like a salesman from yesteryear - they can take a look at your problem, and offer you a way to fix it, rather than just selling you a product.

Packhelp worked closely with Raylo to diagnose their packaging problems and create the ideal standardised solution. See the full story here.

Consolidate your suppliers and vendors

You spend a lot of time managing the relationship you have with your suppliers - each and every one of them.

But is it really worth maintaining a relationship with a vendor if you’re only buying a single product from them because they’re fractionally cheaper?

Probably not.

Sourcing as many products from the fewest suppliers as possible means that you’ll spend less time and energy nurturing those relationships.

Being less financially spread over fewer suppliers can add value in many ways.

One account with many regular purchase orders means that you can get more products delivered at one time.

Getting more products to you in one delivery is something that a supplier wants to do, too.

This often leads to a drastically reduced lead time, in order to get you what you want, sooner.

Note that it’s a good idea to have a backup supplier, just in case.

Communicate

Communication is the key to any healthy relationship, be it personal or professional.

Keeping in contact with a supplier and managing expectations throughout all processes ensures that everyone gets what they want when they need it.

When problems do arise, good communication is needed so that both parties stay on the same page and work through the problem.

Conclusion

It’s important that both supply chain managers and procurement specialists are familiar with the lead times of their suppliers.

If you’re one of these people, in-depth knowledge about the lead time in procuring these products can help you manage an efficient supply chain, and keep orders going where they need to go.