Offset vs Digital Printing & Their Impact on the Environment

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

Offset vs digital printing - many small businesses and individuals curious about industrial printing ask the question:

What is offset printing vs digital printing?

Both methods are unique in their own way and excel in certain areas.

But both offset and digital printing have different effects on the environment and create a different carbon footprint.

If you're curious about VOC's, wastage and production efficiency, then the offset vs digital battle is important.

Digital printing is a quick and easy way to print lower volumes that requires no setup.

Offset printing, also called lithographic printing, is a method that helps produce large quantities in the most cost-effective manner.

At Packhelp, we use both offset lithography and digital printing depending on the number of units ordered.

If you're a small business looking for custom packaging supplies, you're in the right place. If you're not, you'll still learn the difference between offset and digital.

In this article, you'll see:

- What is offset and digital printing?

- How do lithographic and digital printers work?

- The environmental impact of offset and digital printing

So whether you're familiar with the printing industry or not, you're about to learn more about the world of offset and digital printing!

Let's dive in.

What is offset printing?

Offset printing, sometimes called offset lithographic printing, is a printing technique where your image is transferred from an aluminium roller, onto a rubber roller with paint, and then onto the final paper.

Offset/lithographic printing is the prefered method for high-volume printing, as it produces fewer emissions and wastage and has a lower per-unit cost.

Lithographic printing is also known to create the best quality printing possible

Click here to see how Yope used a detailed design and custom packaging to stand out from their competition

However, this definition is very simple.

Of course, offset printing can be explained a lot better by diving into more detail.

How does an offset printer work?

There are 3 main rollers in an offset printing machine.

- A plate roller, which holds a sheet of aluminium with your design etched on it

- A blanket roller, made of impressionable rubber

- The print roller, which carries the paper sheet.

There are also smaller rollers that apply water to the plater roller (the roller with your image). This water sticks to the non-image parts of your design on the plate roller.

The ink is applied to the roller plate. But since water repels oil-based ink, the ink only sticks to the image areas of the plate.

The inked image on the plate roller is then transferred (or 'offset') onto the rubber blanket roller, which is then pressed onto the paper on the final print roller.

This image gives you a simple idea of the process:

The above-mentioned process can only apply one colour at a time.

The earliest lithographic printers could only print one colour at a time, so dyes had to be changed and rollers washed any time a second colour was to be added.

That's why modern offset printing machines multiply this process by 4.

Each roller is responsible for one part of the CMYK colour palette.

Using Computer-to-plate technology, your design is broken up into 4 separate images according to the colour spectrum - Cyan, Magenta, Yellow and Key (black).

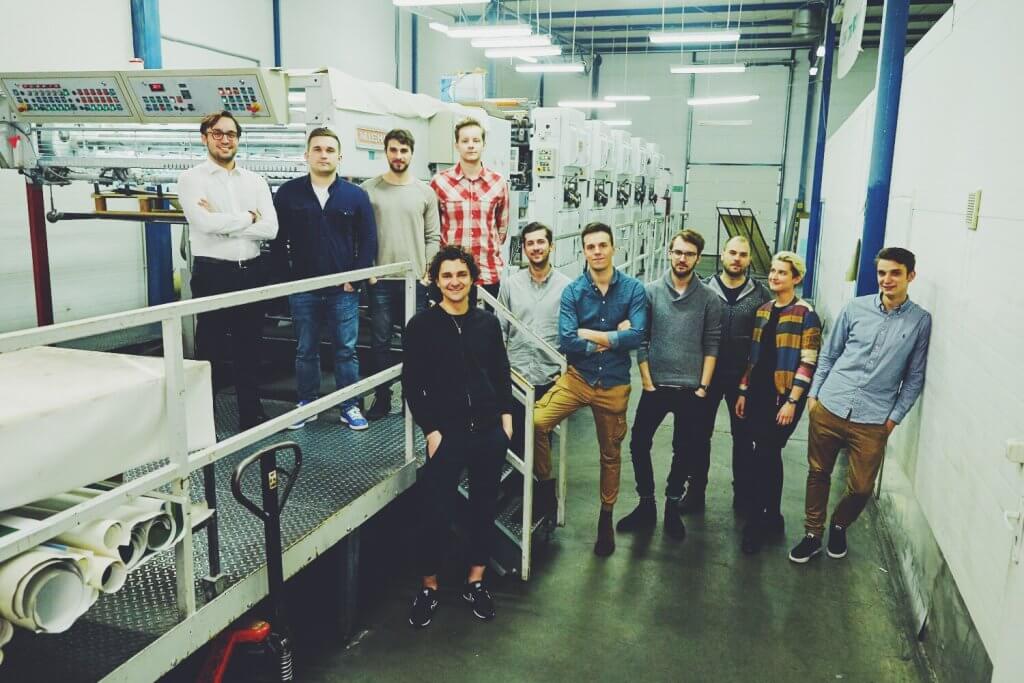

Below, you can see an image of Packhelp's founders with the 22-ton offset printer, Miehle 78 REN.

There are only 16 of these in existence, and this is the only one in Europe.

This machine is used to produce a majority of our products, the most popular being the Eco mailer box and Full-colour mailer box that you can see below:

Click here to see how Loella use lithographically printed colour boxes in their branding

After the image is printed on the surface of the paper, it's left to dry. If your design was printed directly onto the cardboard, it's now ready to go!

If your printed paper still needs to be glued to its cardboard packaging, that's the next step.

What is digital printing?

Digital printing is a printing process that digitises your image.

This information is then used to plot and print your image. Most forms of home printing are digital printing at work.

How does a digital printer work?

When printing digitally, your picture is first broken up into the CMYK spectrum, not unlike lithographic offset printing.

The digitised versions of these 4 images are then sent to the printer. Rather than one layer of each colour being printed at a time, microscopic dots are printed.

The digital CYMK values are used to control the colour of each dot as well as the location.

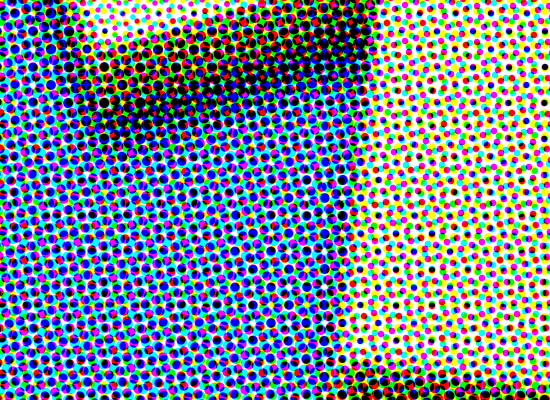

This is a microscopic photo of a billboard digital print:

Inkjet printers (like home printers) place liquid ink onto the paper, whereas toner-based printers use a fine, plastic-based powder that is instantly dry.

It's worth noting that digital printing releases more VOCs (Volatile Organic Compounds) at higher volumes - more on that later.

Digital printing vs offset printing - What's the difference?

To the untrained eye and your final consumer, there are little to no differences between these two forms of printing.

However, when your business is presented with a choice between digital and offset printing, there are a few things you need to know:

Turn around

Digital printing is extremely quick to set up. All that's needed is a digitised version of your image and perhaps calibration of the machine for the size of your piece.

This means that you can have a small number of prints done on the same day, perhaps in a matter of hours.

Below, you can see a picture of an industrial digital printer, like the one used by Packhelp:

Lithographic Offset printing, however, requires significantly more time to set up.

Your design needs to be split up and etched onto 4 separated aluminium plates. These plates need to be inserted into the machine and calibrated correctly.

This is a time consuming and labour-hungry process and has a higher cost per unit when low volumes are ordered.

Cost-effectiveness

Offset machines require more maintenance and need to be cleaned in between each job.

More moving parts also means more parts can break. For these reasons, offset printing is more cost-effective at higher volumes.

Digital printing is usually used on a smaller scale. This is because there is less of a setup cost, turn around time is quicker, but also comes with a higher cost per unit.

With offset printing, the price-per-unit decreases as the number of units increases.

At Packhelp, we usually switch from digital to offset printing at around 500 pieces. Browse our range of custom printed packaging products

Colours

Digital printing is limited to printing in greyscale (black and white) and the CMYK palette. True colours, like Pantone and HKS, can't be achieved with digital printing.

Offset printing has long been known to a more accurate print, making it great for detailed designs and true-life recreation of textures. Highly-accurate inks such as Pantone can be used to create an even more accurate image.

In the following image, the left is lithographic and right is digital:

Digital printing can, however, take into consideration the way that the paper (stock) affects the final colours, and adjust the colour levels accordingly.

Paper (stock)

You can't talk about colours without talking about paper - or stock, as it's called in the industry.

Industrial-scale digital printing uses paper that's already coated with a protective layer. The ink sits on top of the paper, rather than being absorbed.

When offset printing, the paper is uncoated and somewhat porous, letting the ink absorb deeper into the paper

This sometimes means that offset prints can be a little duller and therefore limits the spectrum of colours that can be effectively used - unless a clear coat is added.

Since digital printing prints on top of already clear coated paper, the colours can be brighter and more vibrant to the eye.

Which one is 'greener' - Digital or offset printing?

While both digital and offset printing create a similar final product, they both have separate and different effects on the environment and packaging sustainability

Click here to see how Onka uses eco mailer boxes as the basis of their environmentally friendly wedding box brand

Note: the following information has come from this report.

Efficiency

Paper usage is usually higher for lithographic printing. This is usually due to material consumption in setting up the machine for a specific type of ink and paper (called 'makeready').

Digital printers often run at 100% efficiency in ink utilisation.

It's important to note though that while it runs at 100% efficiency, digital printing often uses significantly more ink.

yellow ink is used to recalibrate a machine after paper jams, which are a common problem in digital printing.

VOC Emissions

VOC (or volatile organic compounds) are elements present in ink that release dangerous gasses in a chemical reaction.

Please note though, that emissions for both offset and digital printing are well below regulatory emissions.

VOCs in the printing industry don't present a health risk to printing operators.

VOC emission Per Impression is higher for the lithographic press in short runs.

However, lithographic printing emits almost 80% few VOCs compared to digital printing when used in longer runs.

This is another reason why Packhelp use digital printing for low volume orders and switch to lithographic for higher volumes.

Environmental impact

Lithographic printing requires the use of aluminium plates to be created for each and every design.

This process is energy-intensive, however, the aluminium plates are melted down and recycled into other aluminium products.

Offset or digital for custom packaging?

As you read earlier, Packhelp switches from digital printing to lithographic printing at around 500 pieces.

While lithographic printing takes more time to set up, it's much quicker to produce high volumes once it's set up and running.

See how Sheyn use a simple graphic on kraft cardboard to create eye-catching packaging

Our lithographic machines are also able to use a wider number of inks - Pantone, metallic and other types can be used, compared to digital ink.

At higher volumes, lithographic printing also creates less waste and emits fewer VOCs.

For these reasons, we encourage brands to place orders for larger quantities (over 500), as this is the point where the print quality improves and the net carbon emissions are smaller.

Final thoughts

To the average consumer, there's no difference between offset and digital printing.

It's only a concern for small business owners who need things printed.

Small businesses may need to weigh up the pros and cons of digital and lithographic printing if value for money is important, as well as the size of the carbon footprint created in the process of using both methods.

Click here to see Packhelp's range of custom printed packaging solutions!