13 Simple Ways Your Business Can Reduce Packaging Costs Now

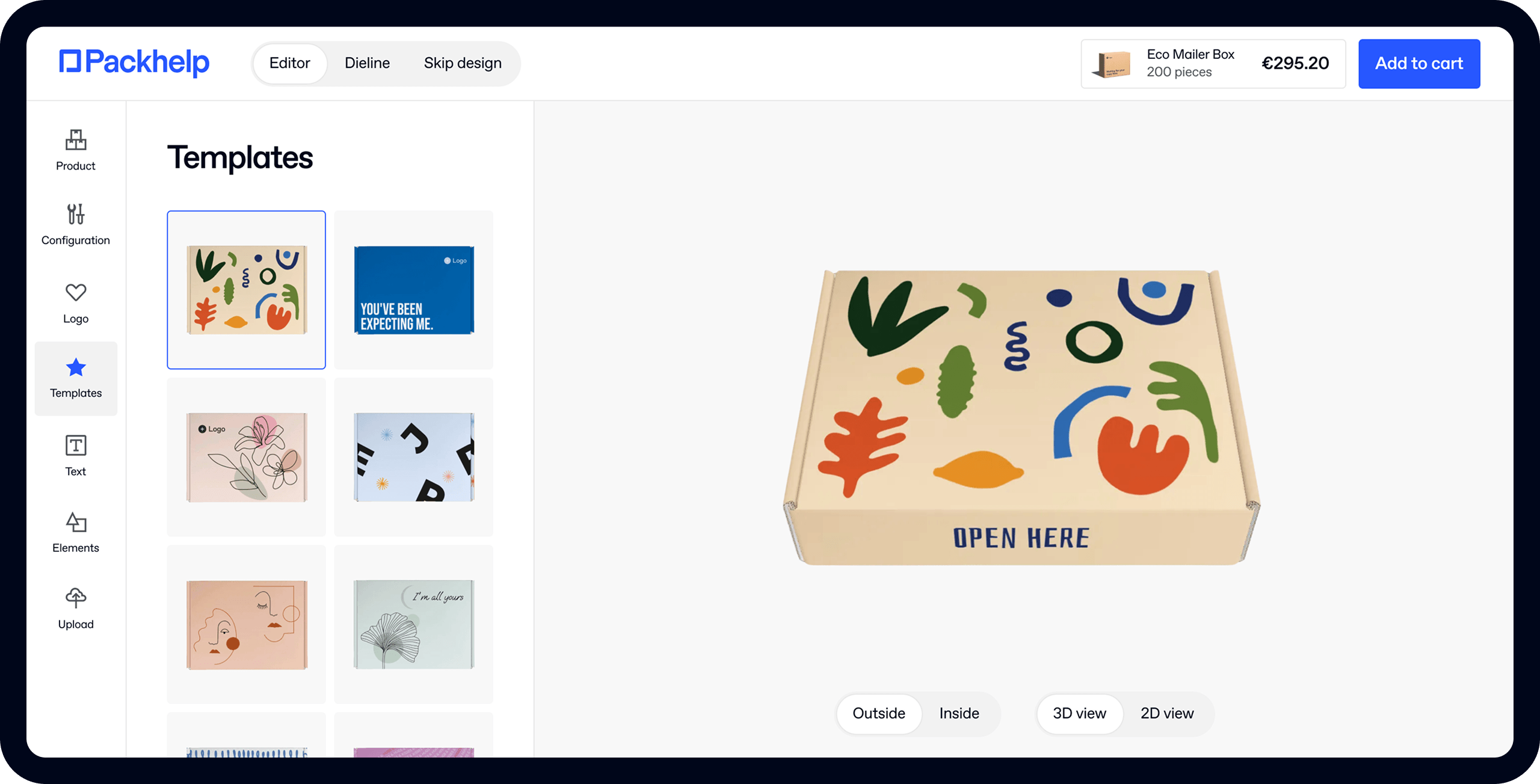

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

- 1 - Train your staff

- 2 - Maintain your machinery

- 3 - Be proactive, not reactive.

- 4 - Packaging isn’t just a box

- 5 - Lower your assembly & packing time

- 6 - Remove what’s not needed

- 7 - Utilise custom-sized packaging

- 8 - Cut down on your Void filler usage

- 9 - Consider multi-function packaging

- 10 - Reduce your number of suppliers

- 11 - Process optimisation

- 12 - Reduce packaging weight & size

- 13 - Follow stock closer

- Final thoughts:

Any wise manager wants to reduce packaging costs all over the board.

But your business’s supply chain is changing, whether you like it or not.

Consumers expect sustainability, the D2C model is changing who orders your product, and customers are pickier than ever.

All these changes mean reinventing the way you operate, in turn, making it harder to save some money in the process.

But despite all these changes, there’s one element that won’t change.

No matter the business model, no matter how demanding your customers are and no matter what they expect, you’ll always need packaging.

The consistent demand for packaging means that it’s a great place to look when you need to start saving some money in your supply chain.

In this article, you’ll see how to:

- Reduce packaging costs

- Save money in order fulfilment

- Use custom packaging to free up cash flow

And as you’ll see below, there are plenty of ways to free up some cash.

But the most effective way to save your packaging budget doesn’t involve your packaging at all:

1 - Train your staff

You can optimise processes and products until you’re blue in the face.

But you won't reduce your shipping costs if the human element of your business isn’t up to scratch.

Well-trained staff are critical to an efficient supply chain and fulfilment department.

All staff must be thoroughly trained on all equipment that’s used in their job.

Local OH&S laws may also state that various procedures with machinery and repetitive movements must be documented.

Whether it’s for employee safety or not, thorough documentation should be used in all processes.

Not only can help onboard new employees and bring them up to speed quicker, but it’s also the first place to look when you want to make these processes more efficient.

Shorter times for employees to integrate means you reduce delivery costs sooner.

Click here to see how Apple lowered their packaging costs on the new iPhone 12

2 - Maintain your machinery

Just like people, if your machinery isn’t working properly, it’s costing you money.

First and foremost, use the right tool for the job.

Just because you can use a broomstick as the handle for your plastic pallet wrapping doesn’t mean you should.

Sure, it saves you money, but when it breaks, you’re without a plastic wrapping mechanism and a broom.

From conveyor belts to lifting machinery to the simple tape dispenser - it all needs to be in perfect working order.

If maintenance of machinery and tools are neglected, you’ll have to pay for both the repairs and then downtime when it does inevitably break.

With the above two points taken care of, you can be sure that any changes now made to your packaging design will reap the best rewards they can.

3 - Be proactive, not reactive.

Chances are that you’re reading this article because something happened.

You’ve noticed your costs skyrocketing, you’re getting more returns, or there’s a massive inefficiency.

But the best time to implement the tips that you’ve read in this article is when there are no problems.

Paying attention to processes and product usage when there are no problems means that you can clearly see how efficient it is and if there are any easy ways to reduce your ongoing packaging costs.

Compare this to auditing your packaging when there is a problem, and you’ll have the added stress and pressure of needing to find savings.

Consider scheduling a packaging audit every 6 months to reassess your packaging supplies, procedures and methods.

4 - Packaging isn’t just a box

Sometimes when you’re so laser-focused on saving money in packaging, you think too much about the most obvious product - a box.

But your packaging expenses are much more than just the humble cardboard box.

To lower your packaging expenses, look at things like pallets, printing methods, return policies and warehouse zoning.

Checkout Packhelp's range of packaging supplies that'll save you money!

When trying to reduce your packaging costs, sure, look at the raw materials like cardboard boxes. But don’t neglect to look at the whole process to really fine-tune your packaging expenses.

5 - Lower your assembly & packing time

Labour is a cost that you’ll have to burden, no matter what.

But reducing the per-unit packaging time is an effective way to reduce the ongoing costs of your packaging.

When doing this though, many supply chain managers have a laser-like focus on boxes.

What’s surprising though is that assembling a box and filling it is often the quickest part.

Adding multiple lengths of packaging tape, either to seal the box or add strength is not only time consuming, but uses another consumable product.

This is where the extra costs are often hidden.

Quality packaging design means the need for less tape, often because of a self-locking mechanism.

Products like self-locking die cut boxes come pre-glued and simply need to be expanded to automatically lock into place.

See how AlexKo uses sleeved mailer boxes to keep her products secure

This not only avoids the need for tape but means workers don’t need to reach inside and manually assemble the box.

6 - Remove what’s not needed

Do you include flyers, marketing material or a thank you note in your customer’s orders?

These things are great for your marketing department, but they wreak havoc on your fulfilment department and your packaging costs.

All this is an added expense not just in material, but in the time it takes to add it to each order.

Removing these elements can help lower packaging costs dramatically.

Consider printing a thank you message in the inside of your product box or adding extra class with a hot-stamped design rather than an extra leaflet inside.

Automate advertising emails to be sent to your customer after they’ve received their order.

This cuts that raw material cost as well as the fulfilment times.

7 - Utilise custom-sized packaging

One growing pain of a growing business is sourcing packaging quickly.

As a result, many businesses overlook packaging and opt for a standard size box.

This type of packaging is cheap, readily available and quick to obtain and a great solution for a fledgeling business.

But while this may work at the start, it’s not financially viable in the long run.

Oversized packaging takes up more space during delivery, thus costing you more to ship nothing but air.

However, a box that’s specifically designed for your product makes better use of the available space.

Packaging that ‘hugs’ your product means only the required space in a delivery truck is used, and less space is taken up on your shelves.

Below, you can see how Snakehive used custom packaging to keep product packaging to a minimum but still make a statement.

Custom sized packaging means less or even no need for void fill, lowering or eliminating both the time and costs associated with filling empty space.

See how custom-sized packaging can save you money. Request a quote now.

Custom packaging is also a fantastic branding opportunity.

Whether it’s shipping boxes that are sent to retailers or packaging that’s sent directly to your end customer, custom packaging and branding go hand in hand.

8 - Cut down on your Void filler usage

Void filler is something that you'd rather not use.

It's an expense that does nothing other than fill up empty space.

But if you’re shipping an oddly shaped product and your packaging design has already been optimised, the use of void filler is inescapable.

Therefore it needs to be designed and used with both efficiency and safety in mind in order to successfully minimise your ongoing packaging costs.

The best option for minimising empty space inside your packaging is to use an insert or fitting designed for each said product.

This holds your product directly in place in transit, meaning less chance of damage, and no need for void fill.

A custom insert can weight and therefore the cost of packaging as it means there’s no need for secondary packaging. It minimises the risk of transit damage and also speeds up the packaging process.

Custom inserts have the added benefit of making a single sized box fit many products, meaning fewer box sizes for you to order and store.

Need a custom insert for your product packaging? Tell us more and request a quote

9 - Consider multi-function packaging

As your business grows and implements more products, the number of required packaging materials can grow exponentially.

This often leads to many similarly-sized packaging products taking up space on shelves.

Save money by looking at all your packaging products and trying to minimise the number of unique products used.

This doesn’t necessarily mean finding a ‘one size fits all’ packaging solution, as this seldom exists.

You may have several products that fit into the smallest size box, but some of them leave a lot of empty space.

See how Coco & Eve use custom inserts to save on their packaging supplies

Rather than a unique box for that product, use your smallest box size, but place the product in a custom insert.

This frees up space on your shelves so you can place higher orders, thus securing a lower cost per unit.

10 - Reduce your number of suppliers

Sourcing products from multiple suppliers is a great way to chew up cash that could otherwise be saved.

Should you decide to change an element of your packaging design, working with multiple suppliers only adds confusion.

Even the slightest changes to design mean you have to:

- Contact multiple suppliers

- Ensure they’re aware of the change

- Modify your order to suit said changes

- Check if the changes meet the requirements of the new design

By using the one provider for all your packaging needs, there’s one point of contact for all things packaging.

See Packhelp's complete range of custom packaging supplies

This not only saves you the hassle of contacting multiple suppliers but can help you cut on delivery costs, too.

11 - Process optimisation

Inefficiencies in any process consume costs and suck up more money than they should.

By taking a look at your current packaging processes, you may be able to find ways speed it up or even completely eliminate steps.

One often-overlooked way to optimise a process is the zoning of your warehouse.

If a worker needs to walk in opposite directions to get tissue paper and a shipping box, this is time and money that’s being wasted.

Remember, an efficient dispatch area doesn’t have to look like a production line.

It should, however, be versatile and set up to handle every product that goes out your door in an efficient manner.

12 - Reduce packaging weight & size

You pay a delivery fee based on either the size or weight of your packaging materials.

So any savings made in reducing the size and weight are savings in your back pocket.

White label products that come in their own packaging, textiles and dry goods are often durable in their own right.

This means that they don’t need a thick corrugated box for the purpose of being delivered to the final consumer.

In this situation, a mailing bag is a great option to implement.

Most forms of mailing bags are flexible, waterproof and add a fair amount of protection without the weight.

Furthermore, mailing bags take up significantly less space and weight than a corrugated die cut box that does the same job.

Bonus: Use a biodegradable polymailer bag to reduce your brand's wastage

Less weight means more delivery savings in your pocket, and the smaller size means more space on your shelves.

13 - Follow stock closer

Too much stock ties up money on your shelves and not enough leads to shortages and delays in fulfiling orders.

That’s why you must know exactly when to reorder your packaging, and know it's lead times.

Working with a vendor that has set production and delivery times means that you know exactly how far in advance to order your packaging.

Use an inventory management system that can automatically place an order for packaging when a minimum threshold it hit.

Such software means that you have to spend less time manually counting stock numbers, and you’re always aware of what’s at hand.

With a closer eye on stock numbers, you can tie up less capital on shelves, and make the most use of the space you’ve got.

Final thoughts:

There are many savings to be had by assessing your packaging supply line. The closer you look, the easier it is for you to lower your packaging expenses.

But it’s important to remember the fine line between saving money and cost-cutting.

The former is what you’re after, whereas the latter ends up being more expensive in the long run.

Quality packaging materials, combined with good design and efficient process will help you reduce the amount of money spent on packing materials, and put that cash into other parts of your business.

Tell us what you need and get a better price on your custom packaging!