Project delivered by the Packhelp team

Developing insulated shipping boxes for frozen food deliveries - Psi Bufet Case Study

Keeping the temperature below 0 C - as well remaining 100% eco-friendly - were the two main goals for Psi Bufet in the area of packaging development.

The result was an innovative cardboard box that can be used to deliver frozen dog food. The boxes are fully sustainable and cost-effective in comparison to existing packaging solutions.

Objectives

Temperature remains below 4 C for at least 24 hrs

Packaging made without plastics

Costs below 2,24 EUR per piece

Results

Temperature below 4 C kept for 48 hrs

Corrugated cardboard, organic honeycomb used

67% cost reduction (compared to other solutions)

Client info

Polish dog industry is worth 675 million EUR

The growth of the Polish dog food market, now with an estimated value of 675 million EUR, creates opportunities for the packaging market too. And PsiBufet, is a new but pioneering name in the Polish dog food industry.

When PsiBufet got in touch with Packhelp, the company had not yet launched. Their mission was to revolutionize the dog food industry by providing pets with nutritional, high-quality food, ready-to-serve. Veterinarians and canine dieticians all had input in developing recipes set to deliver a new, better quality product to the market.

PsiBufet’s business model is based on regular deliveries, on a subscription basis. Customers receive their package every two to four weeks. Every first order includes all of the products, so that the doggo can taste the entire range. The specific diet is adjusted after that test run.

Subscription model

Frozen product

Made with vets

Discovery phase

Testing various packaging materials for insulation

The project for PsiBufet was developed as part of the Packhelp Lab, where packaging experts deliver innovative solutions and optimize existing packaging designs in terms of costs, materials and many more aspects.

During the discovery phase, the Lab team manually tested many types of packaging materials and designs to understand the strengths and weaknesses of each solution.

The initial brief required similar properties to styrofoam, however also needed to be eco-friendly at the same time.

Among the tested materials were:

- styrofoam,

- plastic containers and bags,

- organic wool

- corrugated cardboard

- paperboard

To conclude the discovery phase of the project, Packhelp’s Lab experts prepared several concepts to discuss with PsiBufet.

Client feedback

Arriving at the corrugated cardboard with honeycomb inserts

After the feedback round, the possibilities were narrowed down to corrugated cardboard as the go-to shipping material. The challenge now was to meet the temperature isolation requirement.

Extensive research created several concepts, such as organic material woolcool, and corn-based foam.

Woolcool was expensive and increased the convection time as it requires manual wrapping of each frozen can. Corn-based foam, on the other hand, was still above the budgetary constraint, however, the convection time was optimized.

The team arrived at another solution – honeycomb walls. After constructing the box and isolating the products inside, the manual tests provided promising results.

Reduced costs & sustainable design

Many packaging products on the market can only be disposed off in landfills. Plastic cooling bags can’t be easily recycled, but many brands choose them simply because they’re the cheapest option available.

As mentioned before, PsiBufet considered cooling boxes made from styrofoam; however, styrofoam boxes with the required thermal insulation properties are significantly larger and therefore cost more to send to the end customer. Not to mention styrofoam is a petroleum-based product and detrimental to the environment.

Other sustainable materials – such as boxes with wool used to isolate the temperature – were too costly. The insulated shipping boxes designed for PsiBufet were made from 90% recycled contents, along with the organic honeycomb walls. Contrary to popular plastic products, cardboard is easily recyclable. Cardboard & honeycomb proved to deliver longer-lasting results in terms of thermal performance, too. As a consequence, the R&D process helped create a cutting-edge solution for food deliveries that’s eco-friendly too.

Key properties

90%

Packaging made from 90% recycled cardboard

24

Boxes kept the temp. below 0 C for 24 hrs

67%

In comparison with other sustainable solutions

Thermal insulation

Controlling the temperature inside the box

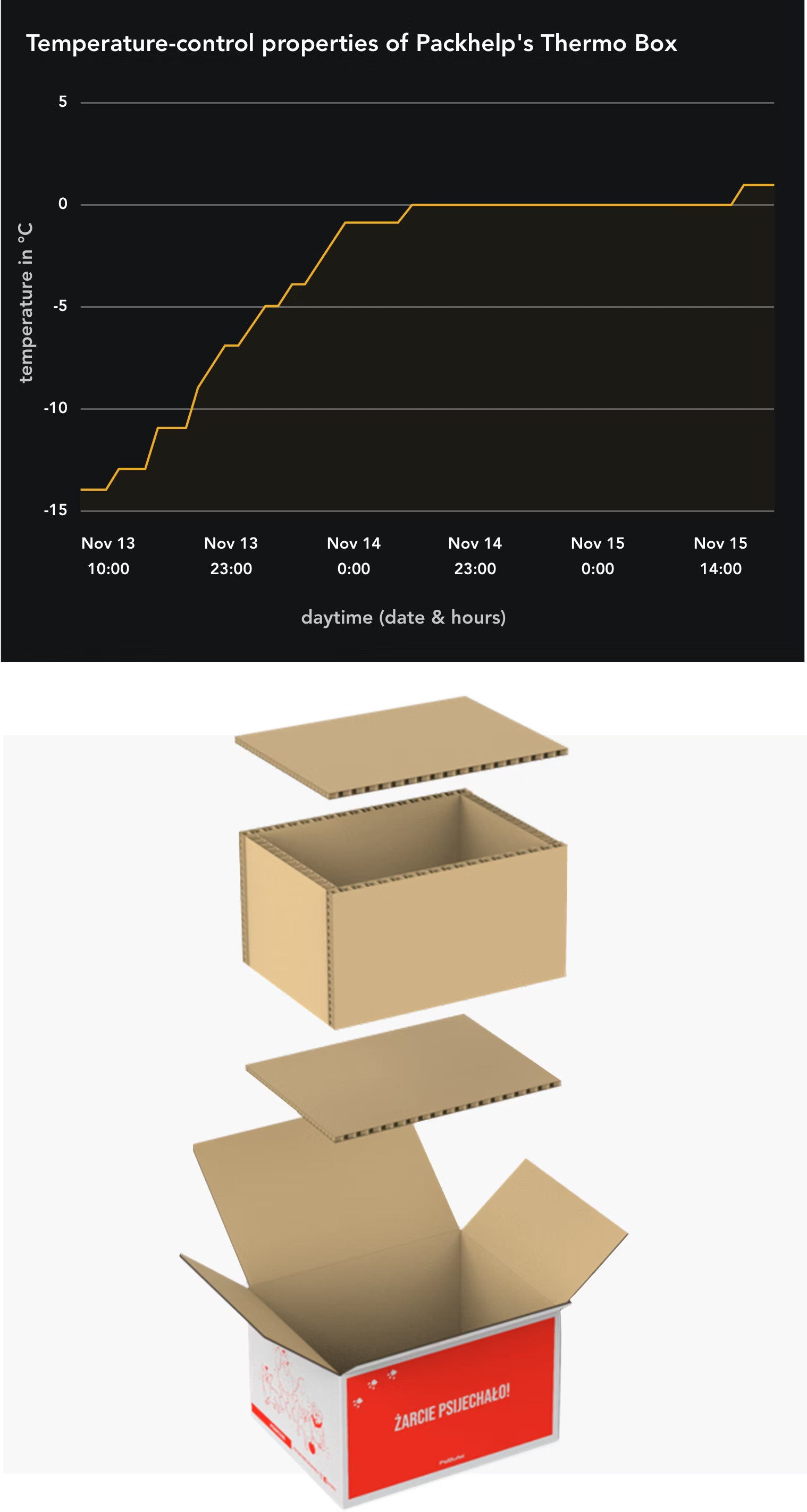

Cardboard boxes kept the product cool for the initial 24 hour period, with a gradual increase of temperature over time. Over the next 24 hrs, the box kept a steady temperature of 0 C. In order to prevent the product from expiring, the boxes had to maintain the thermal isolation effect over at least 24 hours.

The graph shows the results of tests made with a thermometer placed inside the tested food product*.

As part of the project, Packhelp also developed visuals for the PsiBufet. The 3D renders helped explain the concept, allowing the teams to discuss the details of the design as well as the printed artwork.

Cost optimization

New solution decreased production costs

During testing, the Packhelp Lab team estimated the price unit of several concepts.

One of the ideas was to use thinner cardboard boxes and use wool as the thermal-control medium. However, this largely increased time that the pouches were kept cool. This solution would also need additional fillers in the form of wool that had to wrap each food pouch individually.

A thicker type of corrugated cardboard (flute B) worked better for shipping. Thanks to a better fit between the packaging and the product, there was no need for additional fillers. Therefore, the costs were reduced by 67% in comparison to existing solutions.

Psi Bufet Case Study - Summary

Insulated shipping boxes

Keep the temperature below 4 C up to 48 hrs

Made from 90% recycled cardboard

Available for further customization