The Main Challenges for Global Supply Chains in 2022 and Beyond

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

The past few years have been a huge wake-up call for supply chains globally. In 2022, the industry is still suffering the consequences of the COVID-19 pandemic, as well as the aftereffects of the Russian invasion of Ukraine.

Factors such as manufacturing delays, material shortages and lack of workforce are haunting supply chains all around the world.

While disruptions are expected to ease in the upcoming years, we’re unlikely to come back to how things were before the pandemic. Supply chains need to adapt to the current changes if they want to operate efficiently and survive ongoing crises.

What does that mean for the industry, exactly? Let’s take a closer look at what is most likely to impact supply chains in the near future, and how companies can prepare for what’s to come.

1. Ensuring visibility across all operations

Supply chains have become increasingly complex over the years, encompassing large supplier networks across multiple locations. During the pandemic, it became evident that the deeper into the supply chain, the fewer companies were aware of what is going on with their operations. As McKinsey found in their 2021 report, barely 2% of businesses have any visibility over their Tier 3 suppliers.

Seeing how shortages often happen further down the line, visibility becomes a crucial aspect of supply chain management. Most importantly, having visibility enables companies to spot risks early, and act accordingly.

It’s why supply chain mapping, regularly gathering information from every supplier tier, and leveraging data analytics to identify pain points early are vital for establishing a resilient supply chain.

2. Diversifying sourcing & suppliers

The disruptions caused by COVID-19 have made it painfully clear that supply chains need flexibility in order to operate efficiently. As such, diversification has become an important part of risk mitigation for a number of businesses wanting to leave no room for unpleasant surprises.

Having different sourcing locations at your disposal, as well as maintaining relationships with multiple suppliers aside from your go-to ones works as a safety net against probable disruptions.

As the supply chain landscape fluctuates between different instabilities, companies are making increased efforts to near-shore production as a way to manage problems before they actually happen. Even though diversifying sourcing as a whole requires additional resources, it pays off in the long run when issues actually arise. After all - it’s better to be safe than sorry.

3. Following good sustainability practices

Sustainability is currently the word on everyone’s lips, and there’s a good reason for that. Even if it might have seemed like companies would halt their sustainability efforts because of the pandemic crises, the exact opposite happened – as EY’s study shows us, 85% of businesses put more effort into reaching sustainability goals.

Why is that? Simply because companies cannot afford to put sustainability aside. Legislators are putting new sustainability laws in many different countries (such as Germany’s Supply Chain Act or the Norwegian Transparency Act, among others), stakeholders demand information on sustainability goals, and customers, as well as employees themselves, expect companies to meet sustainability standards.

Preparing a code of conduct for the suppliers you work with, as well as carefully verifying whether every supply chain level meets sustainability standards, and strengthening internal as well as external collaboration ensures everyone is on the same page regarding a company’s ESG goals.

4. Monitoring customer demand

Changes in customer demand during the early phases of the pandemic were a huge challenge for supply chains worldwide. As data shows us, during lockdowns, people were rushing to buy basic home necessities (such as cleaning supplies or packaged foods), but significantly decreased their spending on things like cosmetics or electronics.

We all remember empty shelves in 2020 for commodities like toilet paper or disinfectants. On the other hand, businesses selling goods that were low in demand found themselves with piles of unsold products.

This is exactly why keeping up with as well as preparing for sudden changes in customer behaviour is essential for survival on the market. Companies should especially make efforts to be able to react to shifts in demand in real-time.

Using machine learning and artificial intelligence to find behaviour patterns of a customer base, as well as moving to on-demand production can be especially helpful when trying to meet sudden surges in demand.

5. Making resilience a priority

Most of the trends we currently see in the industry have one goal in common: to make supply chains more resilient. This doesn’t come as a surprise since, as recent years have shown us, focusing on day-to-day operations without proper planning for possible disruptions is a recipe for disaster.

It isn’t that resilience is a completely new concept for most companies, far from it. But ever since supply chain disruptions have become more common and unpredictable over the years, resilience has become more than simply managing risks as they come, but rather a way to build a strong competitive advantage.

Make sure you’re prepared for multiple scenarios by testing how your organisation would be able to respond to them, and verify where improvements need to be made in the process.

Increasing the inventory of crucial materials and products, carefully verifying and diversifying the supplier base, as well increasing the collaboration and information sharing with suppliers all contribute to a more resilient supply chain.

6. Embracing digital transformation

If there’s one thing that shines through the recent disruptions in the industry, it’s the fact that supply chains need modernisation. Digital transformation had been already been a discussed topic way before 2020, but the crises significantly accelerated the process of supply chain digitisation.

And seeing how since 2020 a large number of organisations across different industries have invested in digital solutions for the supply chain and plan to keep doing so in the future, it’s now become a matter of adapting or perishing.

Navigate supply chain disruptions with Packhelp PRO

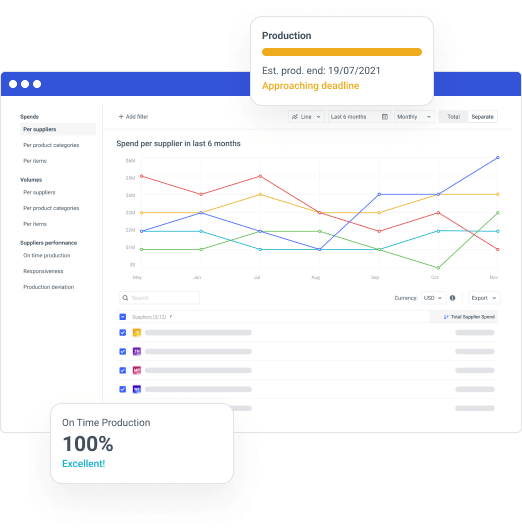

Technology gives businesses an opportunity to solve most of the problems that supply chains face nowadays. Being packaging partners for over 50,000 companies worldwide, we saw this as an opportunity to create the ultimate software for overcoming supply chain challenges: Packhelp PRO.

Through the software, you gain end-to-end visibility over all your operations, a way to streamline the collaboration with your suppliers, mitigate risks thanks to detailed analytics and optimise costs as a result.

Sounds promising? Learn more about Pakchelp PRO >>