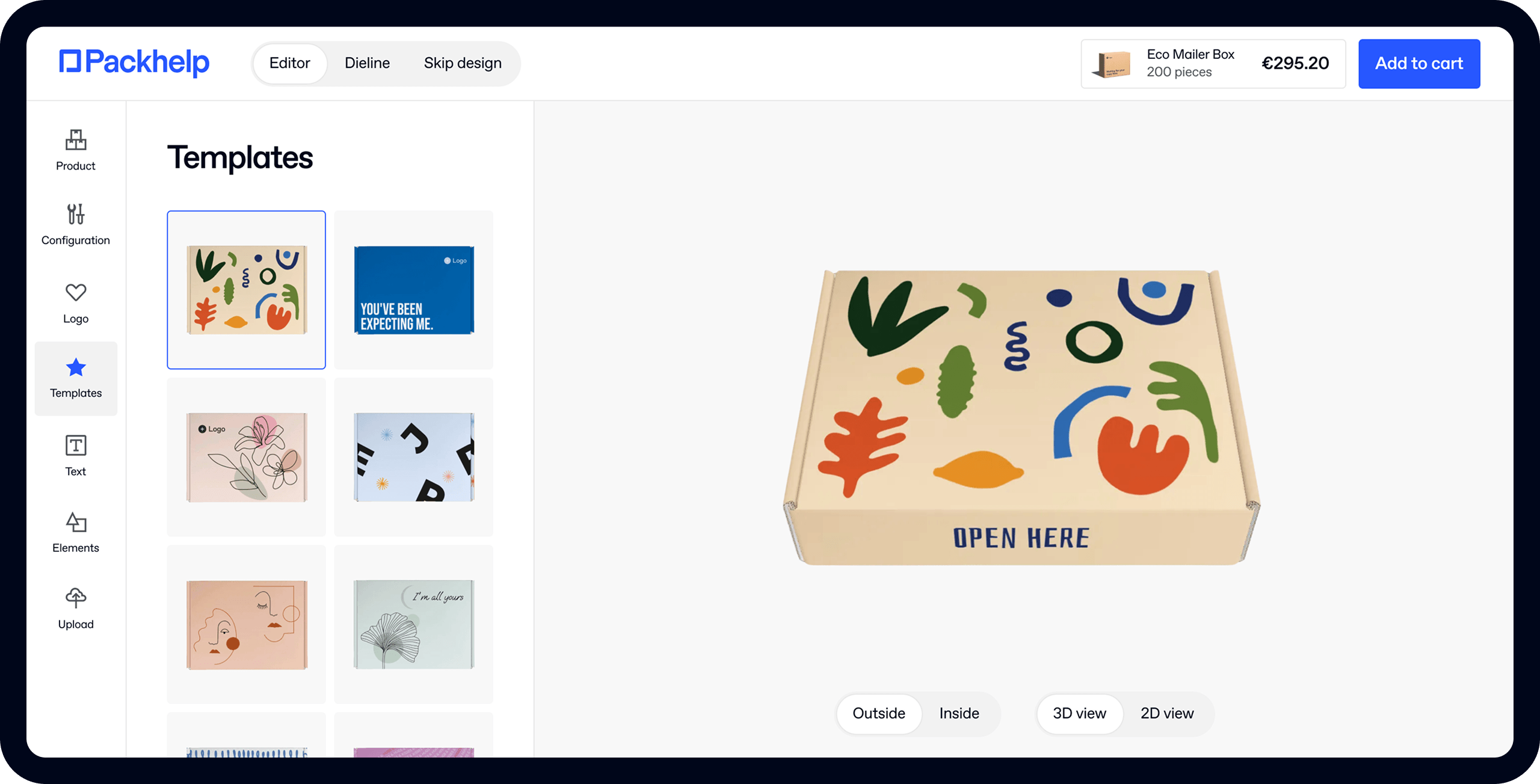

Custom Packaging & An Optimised Fulfilment Process

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

The fulfilment process is dynamic and only growing in size and complexity.

Every day there are opportunities to improve efficiency and find savings for your business. Whether you’re direct to consumer (D2C) or Ecommerce is irrelevant. Either way, you need to be continually searching and testing new techniques to improve performance.

Custom packaging presents a unique opportunity to optimise your fulfilment process. It’s not the first thing that springs to mind, but that’s why there’s enormous value for your business and it’s fulfilment costs.

By changing something as simple as the internal material of your packaging design, your brand can save thousands and free up cash.

In this article, you’ll see many more examples of custom packaging saving money for brands like yours.

In this article, you’ll see many more examples of custom packaging saving money for brands like yours.

You’ll also see:

- What is fulfilment optimisation

- How custom packaging can optimise the fulfilment process

- Fulfilment methods and techniques

- Fulfilment optimisation strategies

What is fulfilment optimisation?

Fulfilment optimisation involves everything that goes into ensuring an order is taken from the shelves, packed and then delivered seamlessly.

This involves everything from the receiving, processing and delivery of orders - of which packaging optimisation plays a huge and often overlooked role.

Packaging is an integral component of the fulfilment process. Your products need to travel all the way from your facility to your customer, whether that process starts at your warehouse or a supermarket shelf.

By optimising the efficiency of your packaging sets, you’ll not only be saving your company money, but you will increase the likelihood that somebody will buy your product.

And that’s why custom packaging is so beneficial here.

Packaging & the fulfilment process

Custom packaging is exactly that - custom.

Rather than using any old box that a product may fit into, custom packaging complements the product itself. This not only adds value to the product but optimises the overall customer experience.

That’s all well and good, but you’re probably wondering how this all ties into fulfilment optimisation.

One of the biggest headaches for an operations manager is finding ways to minimise fulfilment costs while still maintaining high levels of efficiency.

Whether it’s finding ways to reduce weight, changing materials or even shipping methods, it’s a never-ending struggle to achieve results.

The benefits of custom packaging being implemented into these processes can help keep more money in your back pocket.

Here’s how:

Packaging Materials

The easiest place to find savings is by taking a look at your materials. While you don’t want to lower quality, switching to a more cost-effective material is a relatively easy step that can be made to optimise your fulfilment process.

Making the change to a different material is an important one and should not be rushed. Be sure to do your research and make sure that the new material still offers the same protection and reliability of its predecessor.

Rather than switching materials, you may have the option to change the packaging product entirely. A good place to start is to review your product portfolio and see which products are ripe for change.

For instance, your ecommerce brand sells t-shirts that are packed in a box. Clothing is flexible and durable, so a box is overkill in terms of secure packaging. By switching to a poly mailer, you’ll be able to send the t-shirt safely, but save money on shipping, labour and packaging storage costs.

Weight Reduction

Unnecessary weight adds cost.

The journey of goods from facility to consumer requires transportation, and that doesn’t come cheap. As a result, you need to be continually searching for methods to reduce the weight of your cargo.

There is enormous value to be unlocked by assessing the weight of your product’s packaging. Traditionally, packaging was merely a purpose of protecting the product that lies within.

But packaging isn’t just protection. It should complement the product and not just form this unnecessary layer of nothingness. Here lies the fulfilment value in custom packaging.

By having packaging that not only protects but also uses less space, you’ll lower the cost of storing your packaging in terms of price and size.

You’ll also be doing the environment a favour.

Which leads us to:

Sustainable Packaging

Optimising the fulfilment process has numerous environmental benefits. Many brands leading the way in sustainable packaging see it as a necessity, rather than just a novelty.

Global companies like Coca-Cola, are implementing sustainability strategies in an attempt to lower their carbon footprint and appeal to the eco-conscious consumer.

Consumers want to see brands like yours pay more attention to the environment. Fear not! You can make your business more sustainable while still optimising your fulfilment process.

Sustainable packaging materials are becoming more readily available for implementation to your fulfilment process. For instance, switching to a starch-based bioplastic will reduce your shipping costs because it’s lighter than regular plastic.

Packaging sustainability isn’t just about using biodegradable materials. For most brands, simply using less can have the most significant effect in lowering your carbon footprint.

Using less material has many benefits.

Less material means less wastage and less energy used to create your packaging supplies. Not to mention the space saved when it comes to storage.

Less material also means less weight. This, in turn, lowers your carbon footprint in both production and delivery.

Learn more about Packhelp and sustainability. Read about our Eco Properties - the collection of characteristics of our sustainable packaging solutions.

Value Engineering

Ask yourself this question - is your packaging performing its function?

Better yet, could it be done more effectively?

Value engineering is about unlocking value at the lowest possible price.

This is where custom packaging really starts to take it to the next level.

Standardised packaging may be cheaper to manufacture, but it allows very little specification flexibility.

With packaging that’s been designed for your sole purpose, you open up a world of possibilities that will have direct savings on your fulfilment costs. Here’s how:

-

Custom Dimensions

Custom packaging allows you to choose the exact dimensions of your packaging. That means your packaging can be built to the precise size that is needed for the product. No more ‘near enough is good enough’ or having to ‘make do’ with standardised packaging.

Now your packaging can be designed so it’s lighter, more efficient and easier to store (more on that later).

There is also value in addressing the internal design of your packaging. Optimising the inside of your packaging allows for less empty space and eliminating unnecessary air pockets.

By reducing the amount of empty space, you can cut even more weight which will save you on storage and transportation costs.

-

Packaging Design

Managing labour costs is a constant challenge for operations managers. The time it takes to construct an individual unit of packaging can be worked out on a cost per unit basis. Now imagine that you could shave 5 or even 10 seconds off that process?

Custom-designed packaging can be optimised to streamline the picking and packing process. This change can save valuable time, which equates to your employees packing more orders in their day.

-

Packaging Standardisation and Unification

Within your product portfolio, there are likely several options where the packaging could be optimised for use on more than one product. By customising your packaging for use on multiple products, you’ll save bundles in production/storage costs and minimise waste.

However, packaging unification doesn’t just end with the packaging itself. Packaging design is not only an integral part of your product’s identity but also within your fulfilment process and costs.

Take Coca-Cola as an example. Recently they unified their packaging on a global scale to only include the main elements of the red disc and the ‘taste the feeling’ catchphrase.

While they haven’t lost any of their brand identity, they’ve been able to dramatically decrease their production costs with this simple packaging unification technique.

In fact, their identity perception has likely increased because there are less key visuals in their packaging design for consumers to remember.

Labour efficiency

Labour efficiency involves the quality and quantity of work produced within a given time frame. It's one of the essential aspects of fulfilment optimisation, and there are several ways to improve it.

Waste

You’ve just seen how custom packaging can streamline the packing process; however, there is also tremendous value in minimising waste. By having all of your packaging pre-cut into the exact dimensions required, you can decrease the amount of unnecessary waste produced.

Making this change will optimise fulfilment costs, reduce your waste percentages and lower your carbon footprint. At Packhelp, all of our custom packaging is pre-cut into the exact size you require eliminating waste entirely.

Automation

In each passing year, newer and more innovative technologies are being developed worldwide. Countries like Denmark are a great example of the automation wave that is ever-present in today’s society.

In the world of packaging, several machines can be introduced to your activities that can save in fulfilment costs. An automatic case erector like the one below can construct a box with no human involvement whatsoever.

Source: Waxxar Bell

This is just one automation example, but there are many options that can be introduced into your facilities.

Whether it’s cartoners, end of line packaging systems or bagging machines, the automated options are plentiful.

It is important to remember that the cost of investment, service and breakdowns need to be factored into your decision making.

Sometimes, it’s simply not worth automating perfectly productive and efficient operations for minimal time or output savings.

Storage

Throughout this article, we’ve touched on how storage is an essential part of the fulfilment process. The cost of storage is one area in particular that can be addressed in terms of optimisation.

Every square centimetre of your facility is measurable in terms of its efficiency and cost.

To optimise your fulfilment costs, you need to ensure that your packaging is using the least amount of space for the least amount of time.

For instance, a custom printed rigid box is already constructed, which means it may be more difficult to store than a double-sided mailer box which is flat packed.

However, the rigid box will not require any labour involvement considering it is already constructed, whereas the double-sided mailer will need either a person or machine to build it.

This is why you must take into account all aspects of your packaging so you can find ways to optimise your fulfilment process and cost.

The conditions of your facility is another critical factor to consider in your fulfilment process. The temperature conditions of your facility can have a massive impact on the shelf life of your packaging.

Certain materials do not cope well in hot and humid conditions. This can lead to unnecessary waste or destruction of perfectly good packaging, had the right conditions been created in the first place.

Dehumidifiers or high-pressure misting systems are two methods to avoid this problem. Remember, when choosing the packaging materials you need to keep in mind how long it will stay in your facility.

Design

Your packaging design is the most accessible communication vehicle for your customers. That’s why you mustn’t cut corners or try to save a quick buck by brazenly messing with the design.

But, there are ways you can make some subtle changes to your design that can help optimise the fulfilment process. Often these changes are not even noticeable to the untrained eye and can have considerable savings in your fulfilment costs.

The beauty of custom packaging is that it allows you to alter or edit every aspect of your design. For instance, you may use a UV coating finish on your packaging.

It may be possible to make the switch to something less expensive like an aqueous coating. A change like this may be minimal in the eyes of the consumer but can create massive savings on your fulfilment costs.

Want to begin your custom packaging journey? Get a quote!

The same can be said of your packaging’s colour choice. Colour choice has its own psychology altogether, but there are potential fulfilment optimisation opportunities by changing colours.

Reducing the number of colours used to create your packaging will reduce production costs. However, even a small change can drastically affect the way your packaging will look so careful colour management is needed to ensure the consistency of your colours.

Outsourcing to a third party

There is always the option to employ the help of a third-party fulfilment company (3PFC) that can handle all of your end-to-end processes. There are a huge selection of these companies that can take the stress away from finding fulfilment opportunities.

At Packhelp, we have a number of fulfilment partners that are eager to help your business thrive:

- Byrd - https://getbyrd.com/en/

- Big blue - https://www.bigblue.co/

- Huboo - https://www.huboo.co.uk/

Fulfilment companies are obviously an asset for your business. But, you need to decide if the investment will outweigh the savings that can be made by optimising your fulfilment processes on your own.

Wrapping up

The fulfilment process is fluid.

You need to be continually searching for ways that your business can optimise processes and find ways to save costs. The introduction of custom packaging into your operations has many benefits and can increase value to your products.

These benefits are evident in the direct cost savings to your business, be it either monetary or labour. Additionally, you can add tremendous value to your overall customer experience by tweaking designs and rectifying issues.

Finally, the environmental benefit of switching to lighter, more sustainable forms of packaging is enormous. Your business needs to keep up with a world that is placing more and more emphasis on the planet.

Hopefully, you’ve picked up some valuable information in this guide.