Podcast: The Jetpack Ep. #4 – A Design-driven chat with Nicolas Gold of SHEYN

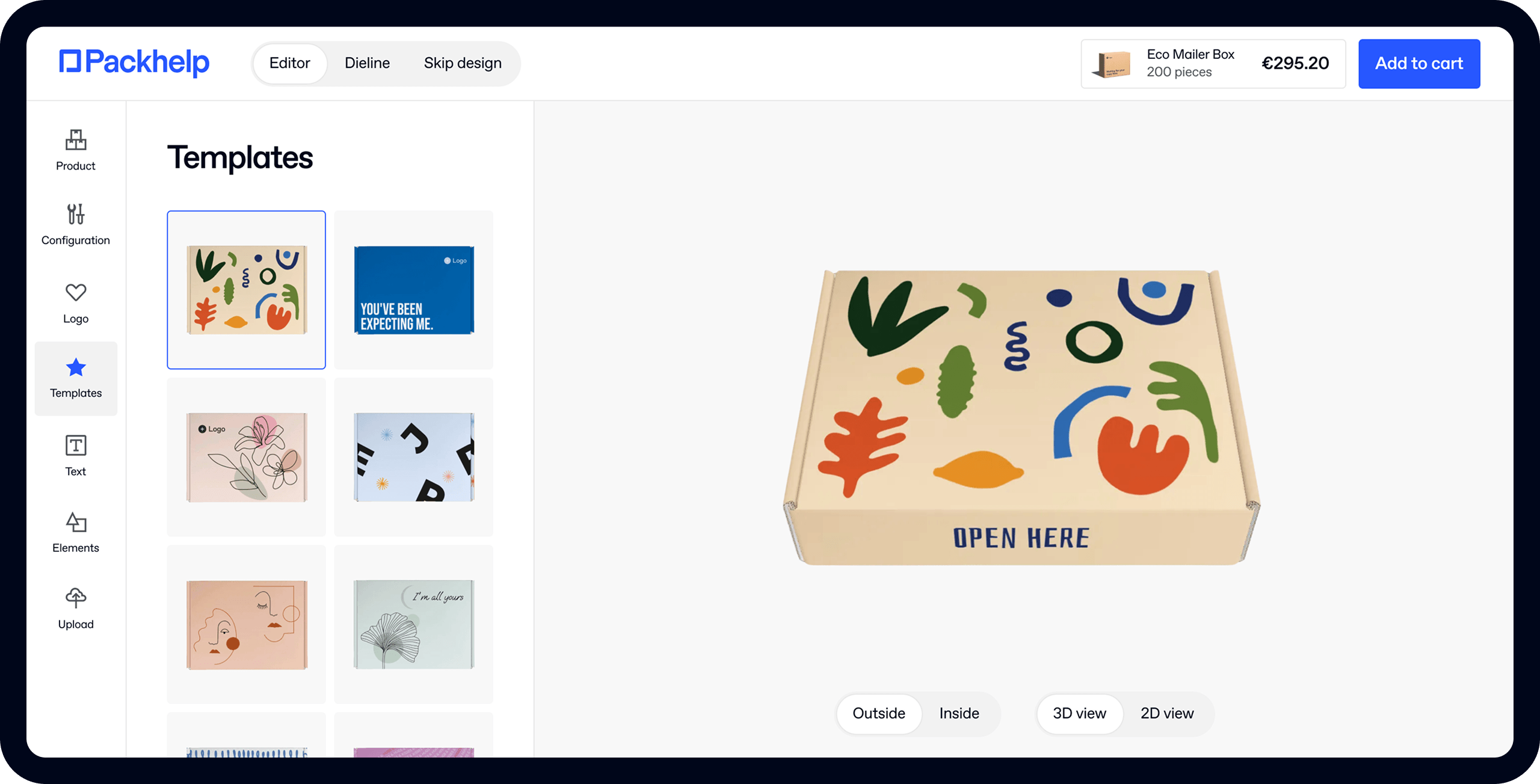

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this new episode of The Jetpack, we're joined by a wildly talented guest. His name is Nicolas Gold.

Nicolas is one of the founders of the brand Sheyn, alongside his partner, Marcus Schaffer.

Sheyn is everything but ordinary. It’s a design studio which produces jewellery and home decor items. The perk, all of their products are printed digitally. It creates a fantastic contrast between innovation and design.

So guys, get your coffee, tea or glass of wine (depending on time) and enjoy!

Kajetan: I’m very happy you found the time to joins us today Nicolas. Let’s begin our chat with your story; what did you do before establishing Sheyn? How did your professional career look before you decided to start your business? What inspired you to work on your own?

Nicolas: I was born in Argentina. I moved to Israel when I was 16 and I was lived there for around 12 years. There I started my career in architecture, I got my Bachelors in Architecture from the University of Tel Aviv and during that time is when I started discovering all of these digital fabrication tools, like 3D printing, digital design, laser cutting, milling machines. And I completely fell in love with the precision of these techniques and tools and I started gaining experience on how to use all of them.

During my studies in Tel Aviv, I had a hard time finding myself inside the Architectural practice. I was never really that much interested into spaces themselves, but rather focused on shapes, geometry and aesthetics. And these tools gave me the opportunity to really express myself as an artist and designer, and I managed to develop skills to create things I was never able to do before.

Then when I finished my Bachelors, I moved to Vienna to study my Masters in Architecture. I studied at the University of Applied Arts and I came to Vienna because the University here in Vienna has a Masters in Architecture program based on different famous architects that you can study under their ward.

I studied under Zaha Hadid. She has always been an icon for me in terms of design. I’ve always been fascinated by her ability to create incredible shapes in the space, which tends to be very conventional in away. But with Zaha Hadid it was different. Her designs are more Avant guard and outside of the box. I wanted to dip my knowledge into it. And then I also fell in love with the city. Vienna is an amazing place to live and an amazing city to create your own brand. Really at the end of my Master’s program, I understood that I’m not a conventional architect who want to sit in an office and ensign buildings. That wasn’t my passion. But I did have a passion for design and technologies. I then started to play around with different scales and began doing jewellery. I just took all the knowledge that I had and started doing jewellery from the eyes of an architect. I don’t have a background on jewellery design or am a goldsmith. I don’t do stuff with my hands, everything that I do is digital. Fortunately, digital printing technology has developed a lot during the past 10 years, especially in the field of jewellery design. It really gives you the opportunity to bring something that you design to life 1 to 1 on the scale that you put on the computer.

All of the jewellery that we do at Sheyn is digitally designed and 3D printed in wax and then cast on silver. In the last couple of months, Marcus and I have been developing our new collection of home elements, which are all 3D printed as well.

Here we’re taking a different direction. We basically have 3D printed desktop machines at our office and all the products that we’re developing for this home collection are directly 3D printed by us. It’s not like in jewellery, where we were a step in between the actual product where we only printed the model that would be cast in the future. Here we produce the product that comes from the 3D Printer, the real product itself.

This is a fast way of telling you what we do at Sheyn. The passion behind it is this passion towards beauty, aesthetics, and shapes, and trying to see really small scales of products.

Kajetan: You touched on many, many topics. I would love to dive into 2 of them. First, I see you decided to study in Israel. From what I’ve heard, it’s a country where many start-ups are established. It’s a very busy scene when it comes to innovative businesses. That’s why I’m surprised you decided to move to Vienna. What pushed you to do this?

Nicolas: I agree with you! Israel, especially Tel Aviv. Tel Aviv to me represents this idea of a city that embraces technology and where something new is always being invented. It has a sense of always pushing people to think outside the box. I guess it could be kind of a Jewish thing, that people are always trying to invent a new thing. It’s something that is very much ingrained into Jewish culture; how can I make something new and improved. This I really took with myself from my life in Tel Aviv.

But it’s also important to make a difference between Israel as a country and Tel Aviv. It can be difficult to develop small businesses. It’s a very expensive country and it’s very expensive to live in. I never saw myself developing my own brand inside of Israel.

When it comes to moving to Vienna, I actually didn’t choose Vienna specifically as a city. I was looking for a masters degree in Europe because I always had this idea of having and experience in Europe and living for a while there. While searching for degree options and I found that the University of Applied Arts in Vienna offered this degree under the ward of Zaha Hadid it felt like a dream.

And I didn’t know so much about Vienna before coming here. But I have to say that Vienna is kind of like the opposite of Tel Aviv. Vienna is more traditional. People are more laid back. People like what they know and they are very sceptical about new things. For me as a person coming from a city like Tel Aviv, it gave me lots of advantages. I like thinking out of the box and trying to invent new things. This is something more surprising for the people in Vienna.

Vienna is also a city that supports a lot of small business owners. Our latest project, Sheyn Home Collection was funded by the Vienna Agency. It’s basically an agency that supports small businesses with money from the state. So there’s a big feeling that city wants to push the creative industry and makes Vienna more of a spot for creativity and innovation.

Kajetan: The cultural painting here is very interesting here. When you spoke about Vienna being a country that leans more towards tradition, is definitely not the way that Sheyn is developed. Sheyn is all about innovation and new thinking. I remember the first time we met, you were ordering packaging from Packhelp an I heard about your business on 3D printed jewellery, and it was very interesting because I never heard of any business like that. I heard about people using 3D printers but not business models based entirely on that.

When I mention the cultural context, it’s interesting that you’re taking the very difficult challenge to change the minds of the consumers that are used to traditional products ad the traditional ways of producing products.

Nicolas: Yeah, I think that 3D printing tech brings new opportunities to businesses to create products without big capital. Sheyn is a company that only belong to Marcus and me and we put our passion and our own money into it.

Basically, if you think about the traditional way of creating products and how big companies do it, they prototype something and the mass produces it somewhere in Asia. They create a huge amount of overstock because they need to produce big amounts in order to sell things at s reasonable price. It creates a lot of problems. Products ten to be shipped all over the world from Asia back Europe. You don’t know who is actually producing the products, what is the quality of the employers, what salaries they get. There are a lot of politics that we don’t want to be a part of.

When we start using 3D printing technologies, we have the opportunity to produce small batches of our product. When it comes to our bigger item we work on a more made to order approach. At Sheyn, everything is virtually done and produced just for the customer who is ordering it. I think with that not only as a brand we have a chance to compete with big companies but we give an extra value to the customer. The customer knows that they chose something that was specially produced for them and he is supporting a local business.

Kajetan: When you say this is the advantage Sheyn has over global companies, I couldn’t agree more. As you explain it in that way and how big companies produce in China or any other country that is known for cheap labour, it also creates a situation where you cut costs on stocking products and warehousing. Of course, it’s not just about costs, it’s about that personal touch that you add to the product and the value that you create. I’m curious though, how difficult it can be to take care of the entire supply chain. From sourcing materials to producing and distribution and even marketing. You’re doing all those things n your own, but in your care, it’s another difficulty of not keeping the product at hand. You are producing everything on demand It’s a very interesting business mode in my opinion. Could you tell me a little bit about the challenges that you have and how do you overcome these challenges.

Nicolas: We encounter lots of challenges. It’s very hard to be a business owner in Europe. Even though Vienna is a great city for things like that, there are lots of challenges. I would divide into two categories; one for jewellery and one for the home collection. Basically, our jewellery isn’t produced in house. We have 2 producers, still in Europe, one in the Netherlands and another in Poland. With them, we create small batches of every single design we have.

We also don’t create any moulds for the products. In the Jewellery business, especially with bigger corporations, it’s very common to make a mould of the products they want to produce and then easily reproduce it hundreds and hundreds of times. These also require bigger capital, but it also creates the idea of overstocking your product, something we are against. Apart from that, a lot of the jewellery shapes that we create cannot be made in a mould. Our pieces are too threedimensional, and so it’s impossible to create a mould a that would not end up destroying the actual jewellery inside.

This is one of the biggest challenges with jewellery, to actually be able to produce small batches with 3d printed technologies and try to price them in a way that allowed us to compete with other names.

I think finding the correct producer is key. We were very lucky to find these producers that were willing to work with a small brand and small batches and want to build a long-lasting business relationship.

In the home decoration department, we’re trying to be more independent. That’s the reason why we try to produce everything in our office with our own 3D printers. We know exactly which products are more interesting for the customer, so for some, we will have small batches already produced. Others will be made to order.

When it comes to home decoration the main challenge is the amount of time each product takes to print. There you require lots of knowledge in 3D printing, how to use the machines to get a really nice product, but that is also doesn’t take 24 to print.

It’s always playing back and forth between the digital design and the print object itself, where you can try to work with the settings in order to create high quality and fast printing.

Of course, being a small business is always a challenge. We had this idea of having our own design brand. In my mind, I would be all the time sitting down and designing. But as we run the business, I realize I spend maybe 20% of my time designing and 80% is spent on marketing, finance, customer service, website design, branding materials. It always ends up being way broader.

You need to be able to divide yourself into al the different aspects that a small brand requires nd be able to take of it yourself.

Kajetan: I can imagine it’s difficult to find resources to develop yourself and grow as a marketer, salesman, and all these areas. There’s much you need to know about and understand. It’s always intriguing for me, how is a business owner as yourself find the time to develop his own skills?

Nicolas: In terms of design, all the skills were brought from my architectural background. When it comes to business skills, it’s a lot of making mistakes and learning from them, honestly.

We try to play with our connection as much as possible. Most of the people that support us from the business side are friends of ours that can support us in different fields. We try to work with people who are close to us and can teach us the skills that we are missing. Even though sometimes it’s easier to outsource what you need, we want to keep all of the knowledge inside the company.

For example, we’re working very closely with a friend of ours on developing a better digital strategy for Sheyn. We do it together with him. In the end, nobody knows Sheyn better than us and we want to have these tools inside the company so in the future when we grow we can also transmit it to our workers. We want to learn from everybody that we connect with and learn to do things ourselves.

Of course it’ challenging, but we are learning. For example social media, Instagram, it’s a very powerful tool. Each month we’re discovering how to improve. It’s our main source for marketing and from where most of our customers come from. It’s our main social media platform where we get to connect with our customers and tell our brand story.

Kajetan: I can recall we met through Instagram when you tagged Packhelp in one of your Images. And now here we are, we’ve collaborated on a few projects with you guys and we’re talking today. I think it’s really awesome. Also, a lot of guests that I talk with me, it seems Instagram is becoming one of the biggest sources of traffic and acquisition for many small businesses. Do you think there is anything specific about Instagram that is better in comparison with other social media platforms?

Nicolas: I think that there are a few things on Instagram that are great for small brands, especially ones that are inside the design and creative industry. First of all, Instagram is all about visuals. It’s all about what you see and what you can transmit through your images.

For a company like us that is very much focused on aesthetics and shapes, it’s a great tool to show what we do. But I think that the main thing on Instagram is that things that are virtual are out of scale. When you see brands like Sheyn next to a brand like Georg Jensen (Danish design brand), maybe the amount of the followers are not the same, but the content can be quite similar.

Instagram really give the possibility to small brands to put themselves next to huge brands. Everyone on Instagram has the chance the get the same attention and open more opportunities.

If you think about it, 50 years ago, when all publicity was in print media or television, it wasn’t accessible to everyone. Today, Instagram is accessible to everyone. It doesn’t matter how big your budget is, you can create amazing campaigns with just 2 dollars a day and as you grow to increase your budget and reach more people.

Kajetan: I’m also curious about the part of the design. I remember when I saw your original packaging design, it really caught my attention. As we talked and discussed writing your case study, you also explained that the artwork on the packaging is actually a 3D model of your jewellery. How did you arrive at this artwork for your packaging design?

Nicolas: When we found Packhelp I actually think it was through Instagram. I was looking to personalise our shipping boxes for a long time. We think that when we ship a piece of jewellery or a home decor piece to a customer, the box is definitely part of the experience. It’s the first thing that you see ad we wanted this box to be part of our branding.

And then we found Packhelp, this start-up company that allowed us to design our own box without having to order 10,000 boxes. We saw it as a great opportunity to order low quantities, see how it worked and then keep printing together.

The concept behind the box came from the idea of wanting to have something abstract but also something that was part of the Sheyn branding. As I’ve mentioned, everything that we do is digitally designed and 3D printed. When you design something digitally you have this great opportunity to design fantastic artworks.

For every jewellery item that we sell we have the digital drawing behind the piece where it shows really precisely how the curves create 3D objects. We use these drawings to show a little bit of how we work and the technology that we use. Then we basically took the drawing of one of our pieces and created kind of abstract patterns of it. You can see it is related to jewellery but you don’t see exactly what it is. We scale it up in a way that the lines are even more abstract and at the moment you fold the box you lose the scale of the object. It’s like a surprise that you can see when the box is unfolded.

Kajetan: And out of pure curiosity, have there been customers that have written you about the box? Did you get any feedback on the design?

Nicolas: I don’t think that people recognized the design itself, but we did get a lof of feedback about the packaging. Especially people that want to buy our jewellery for presents, they think it’s a great box to be given as a present They say it’s not just the jewellery itself, but the box works as well.

We even created this part inside our website where we explain our branding, and there is one page dedicated to the story behind our shipping box. We know that this gives us a lot of opportunities to show our customers what they aside from the product itself. The shipping box is a really cool marketing object to show we appreciate design.

Kajetan: Quickly jumping back to the topic of design and your experience with design, what are your thoughts on the upcoming trends in design? What’s popular now and how do you see design changing?

Nicolas: I think one of the trendiest topics in design today is the issue of getting a more personalised version of what you buy. By this I mean, not going to a store and buying a product that is mass-produced, but that you can influence even a littl bit on the design of the object. I think this is something that 3D printing is supporting a lot.

For example, one of the vases we have on our site is composed of 2 colours, one on the top part and another on the bottom. On the website, we offer over 144 different colour combinations. A customer can go to our website and create almost any colour combination that you can imagine.

And this is something that is only possible with 3D printing. We would not be able to have 144 different colour combination in stock. This gives the customer a feeling that is not only 3D printed, it’s also designed by the person even a little bit.

This topic of personalisation and made-to-order is a strong upcoming trend. I think things are going a little bit more local. We see this a lot in Austria. People are very much interest in where we produce our products, where the materials come from. People are becoming more educated when they want to buy something and know where it comes from.

Kajetan: Another trend that we are seeing is sustainability. We see that more and more brands are looking for a more sustainable way of doing business. How do you approach sustainability at Sheyn?

Nicolas: I completely agree with you. The ecological topic today is very very strong. Actually, we thought as taking it as one of main goals. We have a lot of different topics inside Sheyn that are related to being sustainable.

The materials that we use for our home decoration elements is called PLA and it’s a corn-based organic plastic that you can always recycle. As you know all the materials that we use for our shipping are also recyclable. The silver that we use in our jewellery is a recyclable material.

We never wanted to force the ecological topic on Sheyn because we know that it’s trending. But basically, we discovered that our ideology behind Sheyn is sustainable on its own. Even our ways of producing are ecologically friendly.

When you think about how big players do it, ordering thousands and thousands of items from China, all the shipping costs an pollution that is created by moving items around the world, we minimize significantly.

In general, I also think that 3D printing technology is a sustainable tool. It gives you the chance to work on eco-materials and work against overproduction, and use only the materials that you need and reduce waste.

Kajetan: That’s pretty cool! When you think about it, the fact that you can limit your impact on the environment by switching your production to 3D printing, it creates so many opportunities. I can see that you guys have this sustainability aspect written all over your brand without having to force it.

Now we’ve reached our quick round of random questions!

Kajetan: What is the one tip for any business owner that you would give?

Nicolas: Never give up.

I think that any person who can dream of having their own business is capable of doing it. It’s challenging, but you have to keep on trying and never give up.

Kajetan: The last packaging that you received. How was it? What was your impression?

Nicolas: It’s quite funny, the last one we received was something from Amazon, so, I guess it’s not a great example. I think that packaging design needs to develop a lot and the tools that you guys offer really give the opportunity to bring something new to the market.

Kajetan: If you could hire anyone in history, who would it be and why?

Nicolas: One of my dreams in design was to meet Zaha Hadid and I was fortunate to have the opportunity. Sadly she passed away and I didn’t have the opportunity to sit with her one to one to discuss the design. The few times that she came to the university to review your designs it was amazing. She would definitely be the one I would hire to collaborate with.

Kajetan: How does the future of Sheyn look like?

Nicolas: We see ourselves as a small brand and we want to keep it that way. We want to stay in this niche of creating more boutique elements. Something that we always want to stand by is this idea of seeing what latest technologies we can incorporate into our business.

Kajetan: Thank you Nicolas fr taking the time to talk with us today. I think that Sheyn is an amazing brand and it was fantastic to learn everything about your business and printing technology.

Nicolas: Thank you for having me! We want to invite everyone to visit our site it’s www.sheyn.at We actually have a gift for the Jetpack listeners. You can use the code dankesheyn you’ll enjoy €10.0 off of your first order.