Value-Engineered Packaging: Lowering Costs & Improving Performance

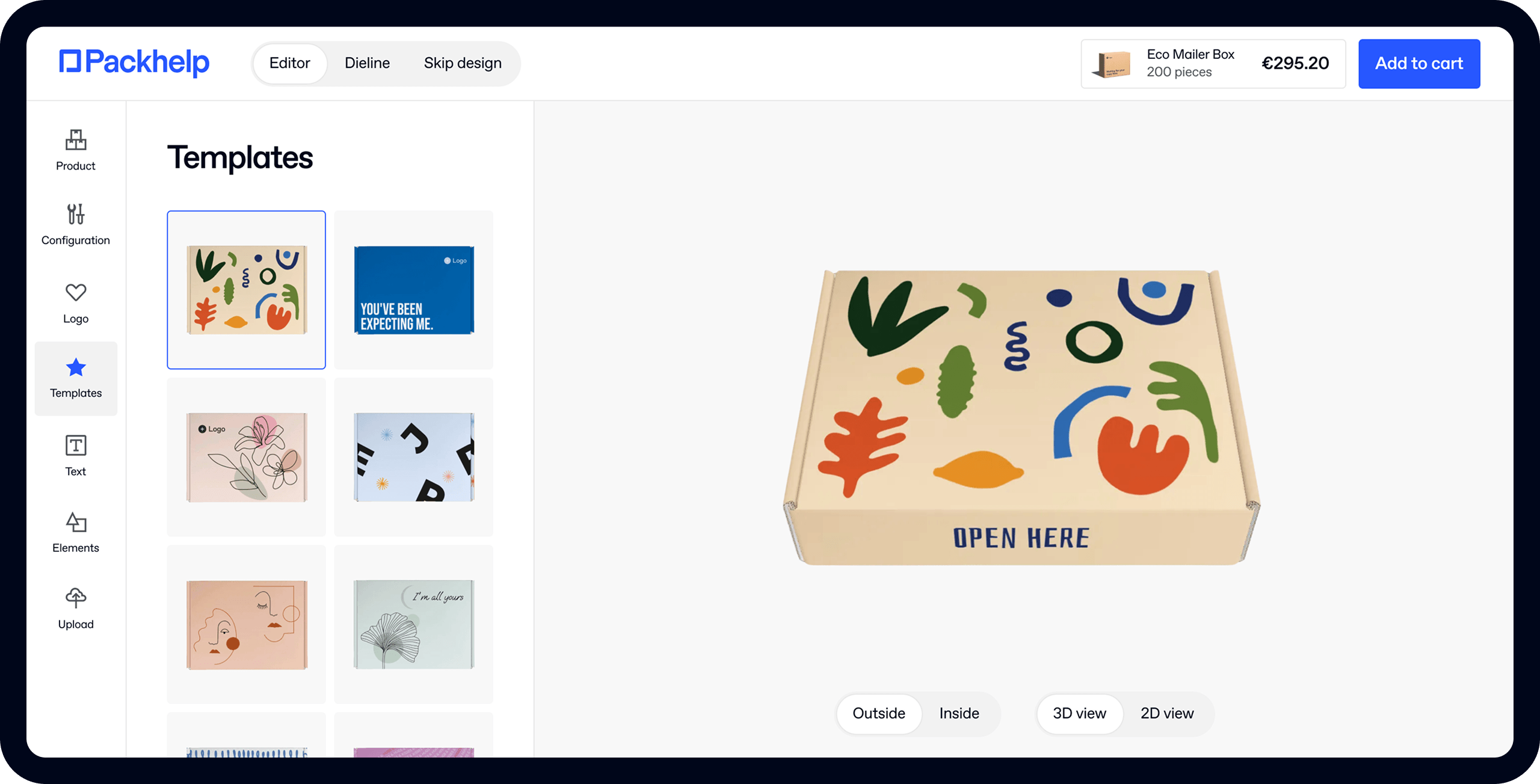

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

Brands selling a physical product all share the need for packaging.

Whether it's vintage posters, truck engines, cell phones or underwear, packaging is an inevitable business expense.

New, old, big, small brands often leave packaging to the last minute when developing and launching a new product.

Stakeholders are often sucked into the 'sexiness' of managing the brand or developing the product, that packaging is left to last.

A go-to, off-the-shelf kind of box is the most common solution when this happens. And while there's nothing wrong with that, this box starts to cost you money as you try to grow and scale your business, a process usually complemented by lowering expenses.

The reality of packaging design is that a standard corrugated mailing box isn't always the best solution.

For most products, it's overprotective, half-empty, heavy, and takes up more space than it should on your warehouse shelves.

The answer to this problem lays in value-engineered packaging.

What is value-engineered packaging?

Value-engineered packaging takes an engineering approach to designing the best possible packaging solution from the ground up.

Costs, security, performance and sustainability all influence the design and mass production of the packaging from the very start of the process.

The result is a packaging solution tailored to your product(s), one that keeps costs down, space and weight at a minimum and increases the efficiency of your fulfilment process.

Value engineered packaging can also create a single packaging solution for several products.

This process, called standardisation, lowers your ongoing packaging costs and helps you leverage the economies of scale.

Here are several concepts to consider if you're considering value-engineered packaging.

Your packaging engineer.

A packaging engineer is an individual that 'does' the design and prototyping of your customised packaging.

Good packaging engineers have a background in design and engineering.

Exceptional packaging engineers have experience with:

- Physics

- Graphic Design & branding

- Materials technology

- Supply chain logistics

- Logistics infrastructure

- Business operations

- Marketing

In other words, a wide range of soft skills is something to look for when you work with a packaging engineer - not to mention years of experience in the role.

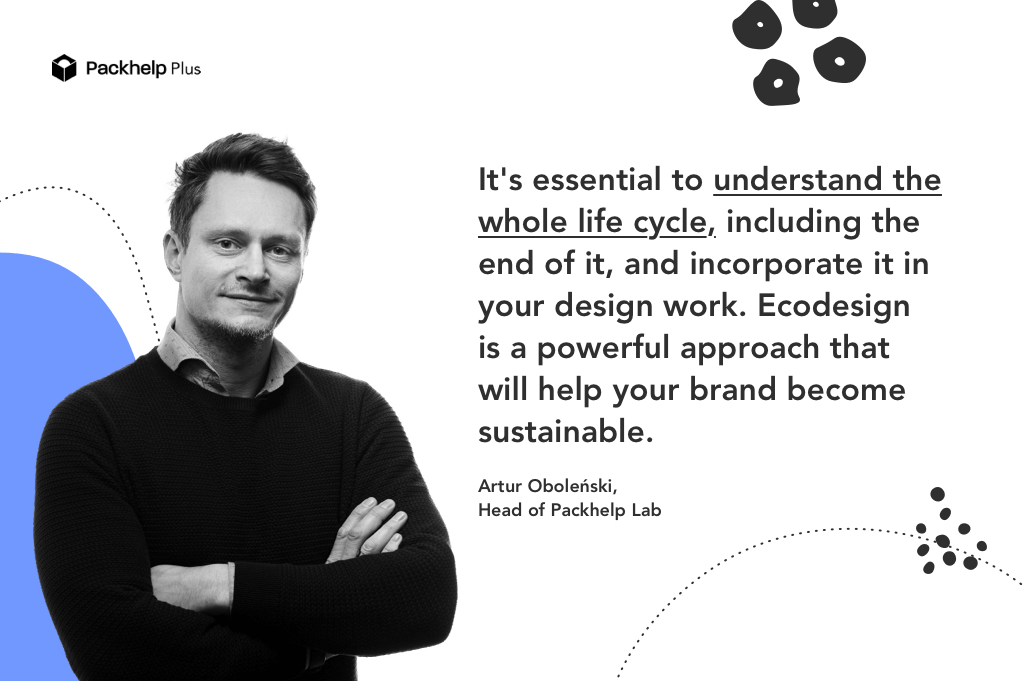

Packhelp's lead Packaging Engineer is Artur Obolenski - an engineer with an extensive work record of designing packaging from the ground up for countless products in a wide variety of environments.

He and his team at the Packhelp Lab work with many small and medium businesses, helping them design a packaging solution from the ground up, with costs and efficiency in mind.

Send a brief of your packaging idea to Artur and his team

Don't reinvent the wheel

Sustainability is a reason that many brands want to value-engineer their packaging.

All too often, we hear of seaweed being the best eco-friendly packaging, furniture that comes in mushroom-based packaging, or mailing bags that biodegrade into nothing.

These are fantastic solutions, and they are the way forward. But they're not always a practical solution for every brand.

Cutting edge packaging materials are usually significantly more expensive, and the raw materials are hard to source.

What's more sustainable than any of the solutions mentioned above is a simple cardboard box designed to remove the need for bubble wrap.

Or a mailer box that meets Royal Mail standards.

Or a simple paper-padded envelope.

If sustainability is your main priority, using less is often the best and most effective way forward.

And this is a theme that's prevalent in all areas of value-engineered packaging - using less and using what's there much more effectively.

Packaging isn't just a 'box.'

If your goal is to create the best box type, you'll create the best type of box.

But a box isn't always the best type of packaging.

Boxes are square or rectangular.

But not everything is square or rectangular, so there's often a lot of wasted space inside said boxes.

Sure, you can pack out that empty space with a void fill like tissue paper, but that's another expense on another product.

What's more, the triple-layer of a corrugated cardboard box is often overkill in terms of protection.

Mailing boxes are the go-to packaging solution for many brands in the world of ecommerce, as they're versatile and cheap thanks to the fact that they're made in such high volumes.

But the truth is that a mailer box may not be the best solution for you.

If it is, a packaging engineer can create a corrugated mailer box specifically for your product that removes the need for other packaging products to fill up empty space.

If a mailing box isn't the best solution for you, an envelope, mailing bag, or cardboard tube may be a better alternative.

When redesigning your packaging from the ground up, it's not about thinking outside the box. It's about forgetting that there's a box entirely.

Sustainability and value-engineered packaging

You read a little about sustainable packaging earlier and how value-engineered packaging can help.

Here's a closer look at why value-engineered packaging is better for the environment than off-the-shelf packaging.

Uses less

Less is more. And packaging designed specifically for your product uses no more than what's necessary.

No surface is too big, no edge too long, and all internal space is used.

Every square centimetre of packaging serves a purpose.

At the other end of the chain, there's less packaging for your customer to dispose of.

Even if that packaging is entirely biodegradable, creating a situation that uses less eco-friendly packaging is a better solution than using too much of it.

Lower carbon footprint

The less raw material you use, the fewer emissions are made to create that packaging and get it to your warehouse. That also means fewer emissions are made when delivering your customer's purchase to them.

Less weight, less size and less raw materials mean fewer emissions all over the board.

Protip: Keep your packaging's carbon footprint even lower by using centrally or locally located manufacturers.

For example, if you're based in Europe, have your packaging produced in central Europe. Using facilities near your warehouse minimises the emissions in your supply chain - a process that's responsible for the most significant part of a small business's overall emissions.

Fewer fillers

The 'value' in 'value-engineered packaging' comes from the number of roles it can fulfil and ultimately eliminating the need for other packaging products.

For example, a box design with internal mounting points and less internal space means there's no need for tissue paper.

Rather than printing separate 'thank you cards', you can leave space on the inside of your box for a hand-written thank you note.

Remove cards with discount codes, and print a QR code on the inside of your box.

Remove the need for tape by using a box with a peel-and-seal strip and perforated rip-tag.

Many of these solutions help your customer - they make it easier for your customer to enjoy your product as they make your packaging the stage that presents your product to them.

This is the genuine foundation of a practical unboxing experience.

Build a better image

Ikea's standard six-pack of drinking glasses come packaged like this:

With the hundreds of thousands of units sold per day, it makes sense that the packaging is plain and straightforward. It does what it has to do and doesn't try to 'sell' - it doesn't need to.

And, it's a fine example of value-engineered packaging.

But Ikea doesn't use its packaging to make a great first impression. People know and trust the brand, so they buy its products no questions asked.

They're not trying to use packaging to build brand identity or create a rapport.

But there's every chance that's precisely what your brand is trying to do.

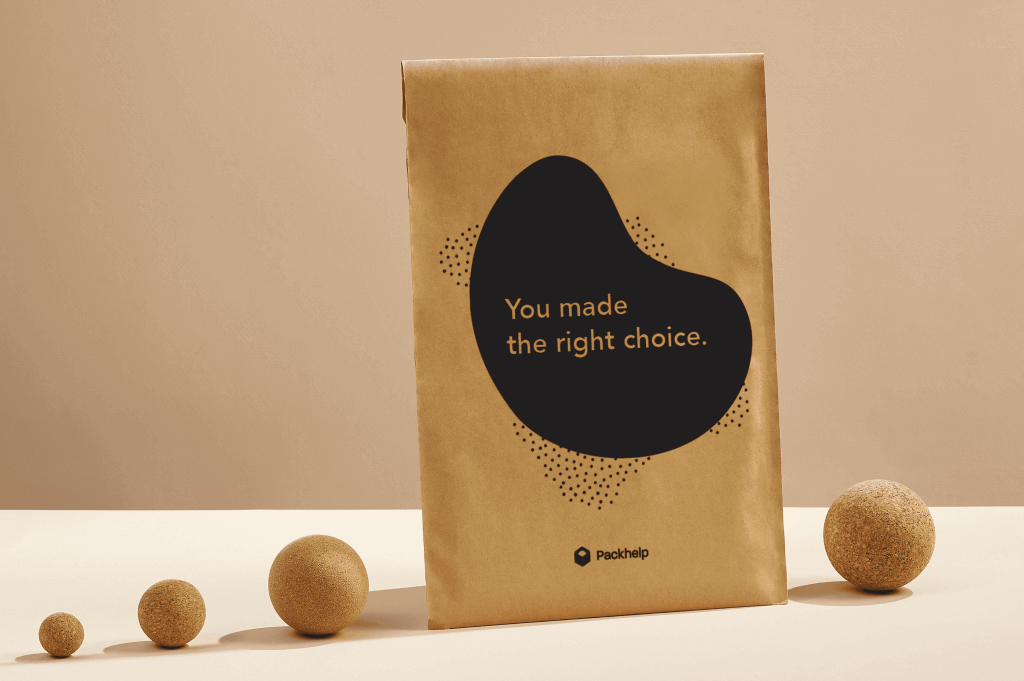

Value-engineered packaging reflects how you feel about your own brand and its identity.

You didn't have to create fancy packaging, but you did.

It's a statement, and it's something that tells your customer that by buying this product, they've got their hands on something special - because they have.

You go above and beyond for no reason other than the fact that you can.

Such attention to details that may not matter shows that you care about all facets of your business.

Little things like this all add up and ultimately make giant steps in the form of building customer engagement, brand awareness, loyalty and boosting word-of-mouth marketing.

Save space and weight.

Investing in a larger warehouse or more storage isn't always a wise investment and is never cheap.

While it may be satisfying when all products fit on pallet shelves and align perfectly, rarely is that the case. You'll always need more storage space than you think.

But any consumable that can be made to fit the constraints of your existing warehouse can help lower the need for that extra storage space.

Cardboard tubes and cans are an excellent packaging alternative, but they don't stack overly well.

The beauty of value-engineered packaging is that the space in your warehouse can influence your packaging design.

A packaging engineer can look at your situation and either suggest an option or let your limited warehouse space influence the design of the tube without infringing on the reasons you use cylindrical packaging.

Lower costs

Value engineered packaging creates a lower per-unit cost. If your packaging design can cater to multiple SKUs, you'll not only be buying fewer packaging products, but you can leverage volume discounts for that packaging.

Your final packaging design will also weigh less and take up less space - both on its way to you and on its way to the end customer.

These lower costs are costs that you can either pocket in order to increase profitability or pass on to your customer to make your products more competitive in terms of pricing.

A single packaging product for more SKUs

Any inventory manager knows the 'joys' of more SKUs to manage. When you combine packaging SKUs with product SKUs, the process only gets even more complicated.

Having a single packaging product that suits more of your products minimises the potential for fulfilment errors.

Value-engineered packaging can amalgamate the packaging for several products of a similar size and shape.

This process ultimately means you can buy higher volumes of that one packaging product, leveraging the economies of scale and putting more savings into your pocket.

Better order fulfilment

Value engineered packaging also has benefits for your warehousing and fulfilment process.

Whether those processes use people or automation, a packaging engineer can create packaging that works within the realm of what you do.

For example, if people assemble your packaging, it can be designed to have a few assembly steps as possible. If it's assembled using machinery, it can be designed to complement this process.

Taking 3 seconds off the time it takes to put together a box, be it by a person or a machine, can add up when you need to assemble 1000 boxes.

Conclusion

Lower costs on unavoidable expenses is an appetising idea for any brand manager.

Value-engineered packaging can do precisely that - lower your immediate costs, as well as your ongoing costs.

It's also a great way to make a move toward reducing your carbon footprint in ways that make a difference and don't cost too much to do so.

If you'd like to explore the idea of value-engineered packaging more, browse our range of packaging solutions and send us a detailed brief on your packaging solution.