Kraft Paper and Its Benefits For Your Packaging Supply Chain

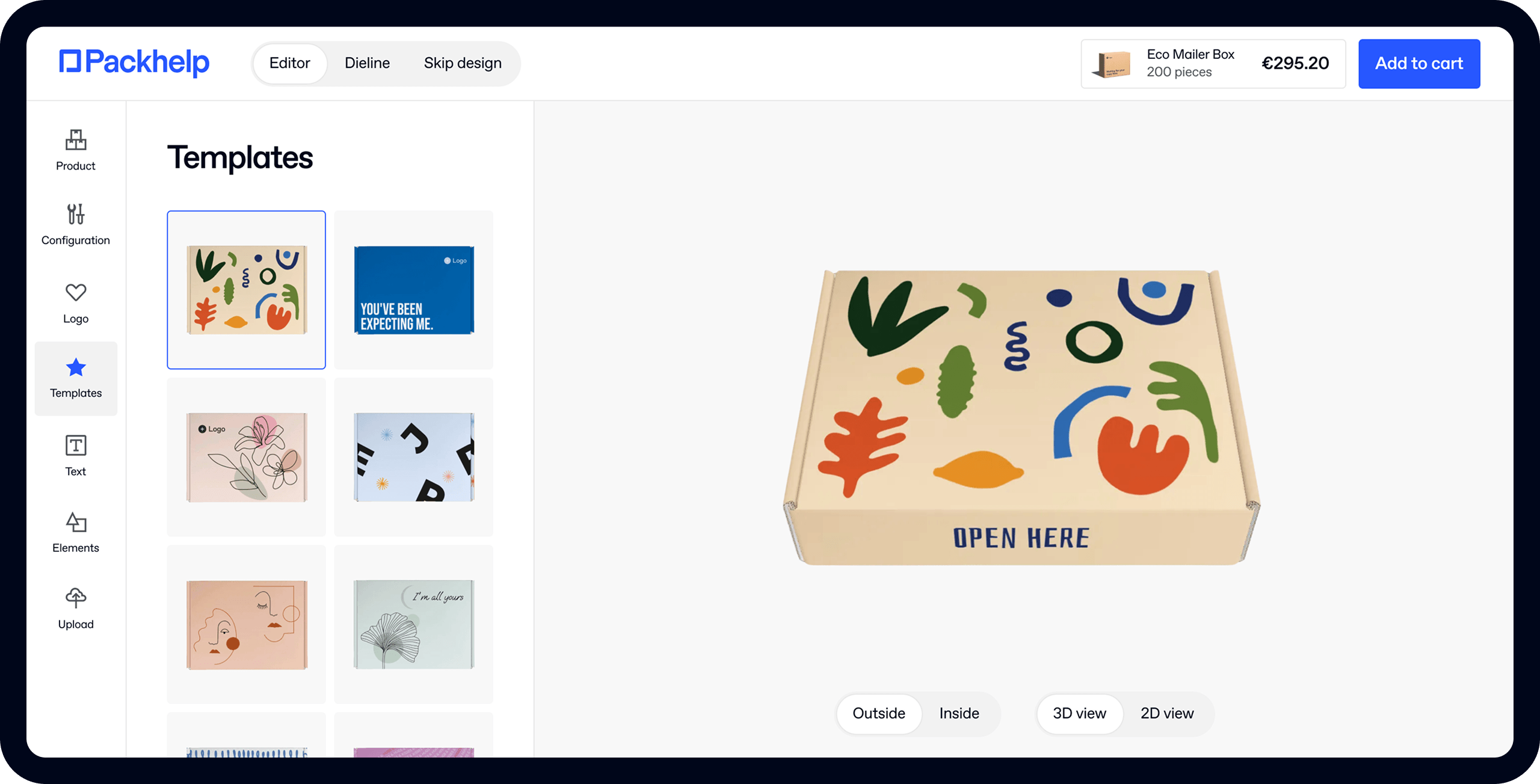

- 200+ templates & patterns

- Real time 3D packaging preview

- Upload logo and choose brand colours

Subscribe now! Receive 15% discount.

Don’t miss out – get 15% off your first order when you join the newsletter. It’s fast, free, and kinda smart.

You're now subscribed!

In this article:

The term ‘kraft paper’ probably makes you think of a few things.

You might picture mum wrapping up your sandwiches for school lunches

You might think of nothing more than a scrunched-up piece of paper in your Amazon delivery.

It might be something you use regularly for craft projects - kraft paper = craft paper, right?

But it might surprise you to hear that in its most simple form, kraft paper is cardboard.

Layers of brown wrapping paper laminated together make the traditional corrugated cardboard box.

But it's also used as a flat, thin sheet.

This leaves it to solve hundreds, possibly thousands of problems, but also have heaps of names:

Brown paper, butcher paper, recycled wrapping paper, packing paper - the list is somewhat endless.

That's because this simple brown paper can benefit your business.

It aids security, branding, environmental impact and saving money.

And you’re about to see how.

In this article, you'll see:

- What is kraft paper?

- How is this brown paper made?

- Using recycled paper in your branding

- Kraft product packaging

What is kraft paper?

It's a naturally biodegradable material, used in a wide range of industrial and commercial operations for packaging and protection.

See how Polu used white on kraft cardboard to make their packaging stand out

It’s natural ‘woody’ looking texture means that it’s suited to a wide range of branding options, too.

The name is from the German work Kraft which translates to ‘force’ or ‘strength’.

Here’s how it gets that strength:

How it's made

Back in the late 1800s, Engineer Carl F. Dahl was working in a paper mill.

His job was to create the best possible paper products.

A few types of paper turned out to not be strong enough for their intended use.

So Dahl started to change the chemicals used throughout the production process.

When woodchips come into the paper mill to be turned into paper, they’re crushed up and mixed with an adhesive.

Dahl found that once ground to a pulp, treating one of the elements of the woodchips with sulfates made the final material stronger.

Hence the name kraft paper - literally strong paper.

After discovering the true strength and versatility of this new material, it quickly became a staple for the packaging industry - and, the food industry.

This new product was a cost-effective solution that, after being coated in wax, was great for meat. Hence the name 'butcher paper'.

Brown paper types

There are a few different types of brown paper that are out there.

The biggest differences are the types of fibres the material is made of (virgin or recycled), but there’s also a difference in the finishes.

Coated Unbleached Kraft Paper is the most basic and common form of brown paper. There’s no altering of the colour, giving it that natural look.

It’s very resistant to tears and can be stiff without being heavy and solid.

Read how Moonsling used negative space and the texture of their product to create a unique packaging experience

Coated Kraft Paper is usually a brown paper that's had a white additive added to make it more of a 'blank' canvas.

Some of the natural texture shows through but rather than being brown in appearance, it’s white.

That makes it a great blank canvas for other colours, whenever there's a need for a custom printed box. This type of paper is used on Packhelp’s Eco Colour Mailer Boxes.

See the role that white kraft boxes play for the German Fashion brand, Hien Le

But kraft can be covered in any colour.

Below you can see how Demagica has used completely black kraft mailer boxes and negative space to create an eye-catching design:

Here are the types of material that are used in both Coated Unbleached and Coated paper:

Virgin kraft paper

Virgin kraft is made from raw pulp. This is wood that has come straight from the tree and is processed into brown butcher paper.

This is the strongest form of brown paper and is used when structural integrity is most important.

For example, in corrugated mailer boxes and kraft packaging tape.

Recycled kraft

Recycled kraft is made from recycled materials. Cardboard boxes, books and other materials are broken down back into pulp and turned back into recyclable brown paper.

This is a great option for brands that want to use sustainable packaging in their supply chain.

Recycled kraft is often used in product boxes, paper bags and paper cans.

Learn why the natural kraft texture is important for Fashion brand Brahmaki

Mixed kraft

This mixed paper is made from both virgin and recycled pulp. It has the benefits of being strong like virgin pulp, but also cheaper and more ethical thanks to its recycled content.

Mixed brown paper is used in cardboard envelopes and other postal boxes.

Benefits of kraft

The main benefit of recycled brown paper is that it’s exceptionally strong, which is a result of its increased sulfur and decreased lignin content.

This stronger form of paper has a lot more durability than alternative materials in most planes and is a lot more resistant to piercing than paper.

Brown paper can be made from many types of wood, like pine, bamboo and oak.

This means it's easier to create, so there's an abundance of it available - this fosters a lower material cost.

The quality of wood can be quite broad, meaning that high and low-density woods can be mixed.

A lot of kraft is made from imperfect trees that aren’t fit for other functions.

Click here to see more about the Certified Paper Pulp used in Packhelp products

As it retains its natural colour and texture, it doesn’t need the extra step of being bleached.

This saves money as the material has to be handled less, and keeps chemicals out of the environment.

Sheyn use minimalism on their kraft cardboard to create a memorable unboxing experience

Waxed kraft was traditionally used to wrap meat, as you read earlier.

The wax coating is what made it ideal for wrapping, as it was somewhat water and moistureproof.

This was a cost-effective solution that led to the alternative name of 'butcher paper'.

Coated and non-coated cardboard is the perfect material for tortilla wrap packaging and rigid tortilla holders.

The chemicals that are used in creating kraft paper are easily recovered and reused, again and again, fostering a circular economy.

Byproducts of the kraf manufacturing process, like tall oil, go on to be processed again and used in asphalt and fire-starting bricks.

Kraft paper & packaging

Pure brown paper is a popular element in product packaging.

It can save your business time and money thanks to its versatility as a packaging material.

Here’s why:

Corrugated cardboard made of kraft is the default shipping option for many reasons.

- It’s lightweight

- It’s durable

- It’s cheap

- It can be custom printed

Since it’s lightweight, corrugated kraft boxes don’t add any extra weight to your item.

Keeping the overall weight of your item down means less shipping costs for you to absorb or pass onto your customer.

Kraft packaging supplies

Kraft is great for filling up space inside a box. We've all seen Amazon and other big brands go hard with their bad packaging:

The fact that it’s lightweight while still being somewhat sturdy means that it can keep the contents of a box safe from thrashing around inside.

Being durable, kraft is a great addition to your packaging supplies, but it's also great at wrapping products to protect them.

Custom-printed butcher paper is a great option for brands that want to leverage the ‘natural’ texture of kraft but also build an unboxing experience.

Kraft branding & design options

This humble brown paper isn’t just adaptable in terms of use. It’s just as versatile when it comes to branding and visual design, too.

The natural, wood-like texture is thanks to the unbleached pulp that when processed, looks a lot like the natural texture of raw wood.

This makes it a fantastic ‘blank’ canvas for many brand types.

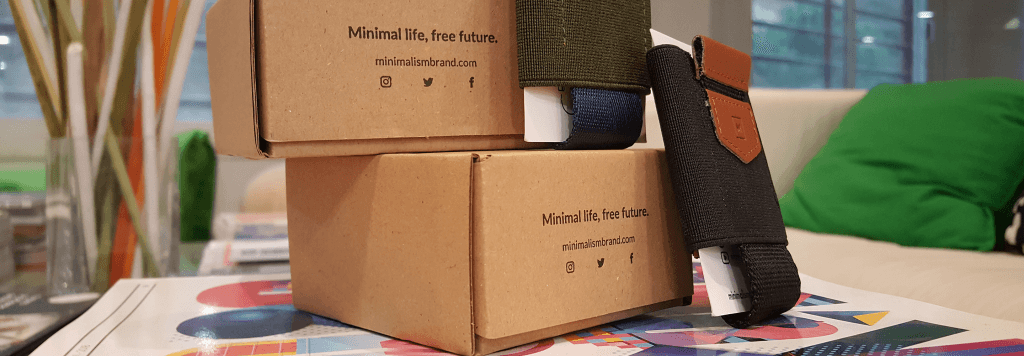

Brands that use minimalism as a design concept often use the simple texture of kraft as a way to focus on that ‘less is more’ idea.

See how Minimalism Brand use the design concept of minimalism to its extremes

Because of its natural look, many ‘eco-friendly’ brands use kraft in their branding.

The look and texture give an earthy, woody feel and help resonate with customers that are looking for an unprocessed, ‘raw’ product.

See how Slopes & Town use their kraft boxes to complement the internal fit-out of their retail store.

Eco benefits of brown paper

Kraft paper is a pretty environmentally friendly material for a number of reasons.

FSC certification

Virgin pulps used in Packhelp products, including kraft, are all FSC certified.

This means while your material made be made from new, raw material, it’s grown, harvested and processed in a way that’s manageable, ethical, and most importantly, renewable.

Biodegradability

If you take coated unbleached brown paper, or corrugated cardboard and throw it into your garden, it’ll start to naturally compost.

Within a few weeks, it will have disappeared back into the ground, and (providing that there are no nasties in the ink) there will be no trace of your brown packing paper left.

This process doesn’t release any bad chemicals into the soil, either.

Economics of scale

If you were to create your recyclable brown kraft from your own trees, it’d be pretty labour (and energy) intensive.

But since kraft and cardboard are such widely used products, the production and recycling process is incredibly efficient.

If a brand wants to minimise its carbon footprint, brown paper and cardboard are a great option.

Not only is the product process energy efficient, but the end product is also completely recycled and also recyclable.

Final thoughts

Kraft paper is something we come across daily.

Its versatility for both boxes and paper gives it a place in your packaging suite as both the protector and a canvas for your branding.

Take a look at Packhelp’s range of kraft paper and packaging solutions and put them to work in your fulfilment process!